I think I can make this seat work.

I measured points a consistent distance back from the back wall of the seat, then used a contour gauge to transfer the inside shape of the seat to paper. I then created an accurately symmetrical profile on my computer, which I printed off and used to cut a bulkhead out of foam core.

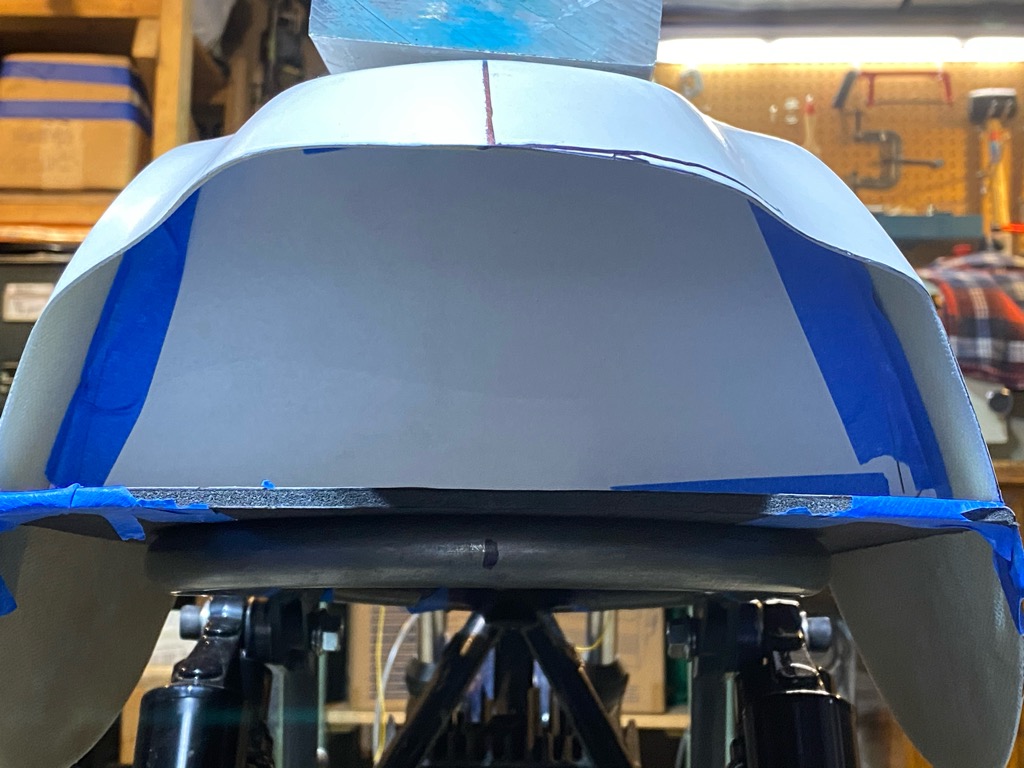

With the bulkhead in place, some painter’s tape all around, and a bit of weight, I have the seat pan fairly well situated. Now it just shows how haphazardly the edges were cut.