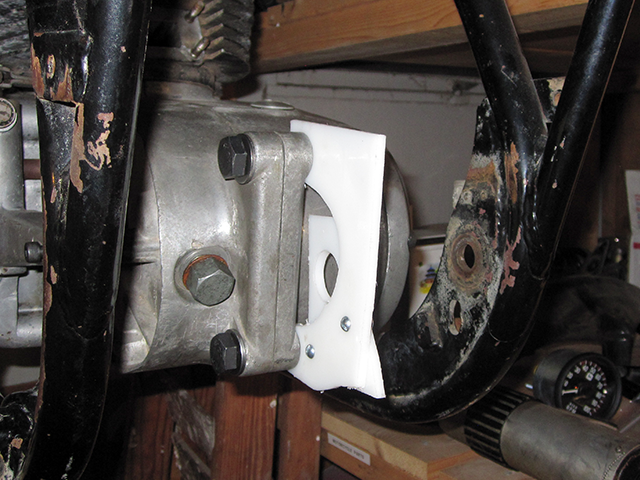

Since I discovered that the Matador rear engine mounting bracket that I bought on Ebay isn’t going to work, so I had to design new rear engine mount brackets. I first drilled holes in two pieces of 3/16″ thick high-density polyethylene sheet—one sheet with two 1/2″ (close enough to 12 mm to work) holes on 100 mm centers, and another with a 7/8″ hole.

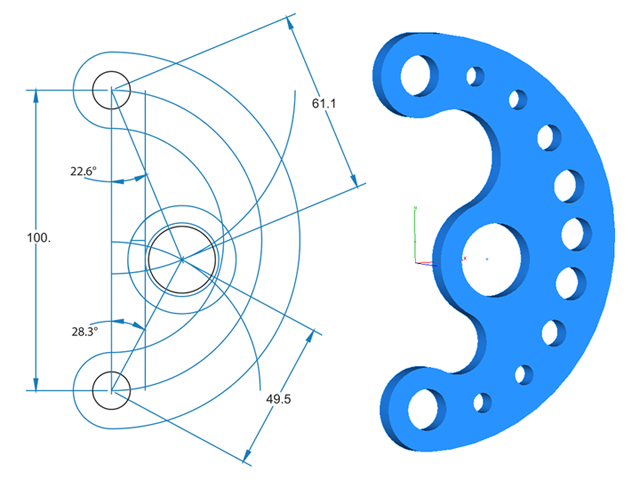

That then allowed me to generate an accurate design. I am going to try to replicate this out of HDPE as a final check before I send the design file off to be made out of 1/4″ mild steel on a waterjet cutter. I’m still undecided about the speed holes.