I felt heartbroken — absolutely gutted. I was installing new bearing races when the frame fell off the bench and smacked the concrete right on the steering stem.

I could take it to a machine shop, but it was a free frame. I’m not even sure what will become of this project; it’s not worth spending a ton of money on it at this point. Having no idea what it would take to make this usable, I thought the frame was trash and this project was over.

I briefly tried heating it with my puny Bernzomatic propylene torch but, as expected, that wasn’t going to do much beyond haze the paint. So, I sought advice online. Most people said One of the guys on the Adventure Rider web forum suggested I try a cold repair. That surprised me, but a couple of other folks backed him up as being a viable approach. So I figured, why not?

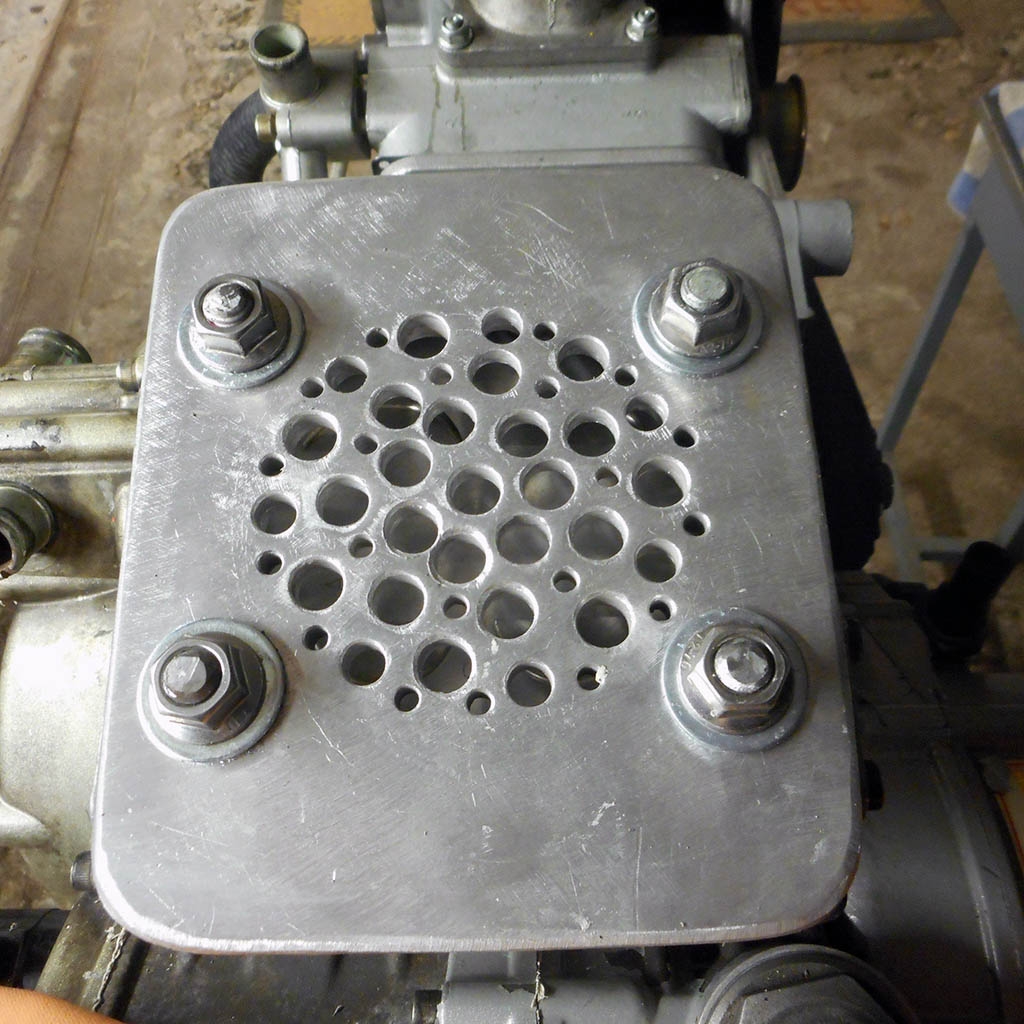

I made up a big mandrel from a heavy chunk of scrap steel (which took a WHOLE LOT of metal hogging on the lathe!). It had a section that was the diameter of the center section of tube, then stepped out to the diameter of the bearing race.

I notched the back to index on the steering stop and keep it from rotating, then I judiciously filed down where the dented lip would be, making a gradual ramp instead of catching the dent on the lip of the mandrel.

Then I got out some all-thread and the impact driver.

It would ugga-dugga about three-fourths the way home, then stop cold. So, I did what anybody would do: I resorted to a bit of persuasion with a sledge hammer! Three carefully-aligned whacks seated it all the way. After I tapped the mandrel out, the inside lip of the steering tube was slightly grunched up, so I cleaned up the edge of the lip with a grinder for about 5-10 seconds. I was then able to seat the mandrel using just the impact wrench.

I decided to use the the mandrel to do double-duty as a bearing driver. When I was ready to install the outer tapered bearing race, I chucked up the mandrel again and turned the smaller diameter section even further, so that the bearing race just slipped over it. After loading the race into it, it slowly ugga-dugged into place. (I did give the bottom of the mandrel one good whack with the sledge to ensure it seated firmly and square.) I was slightly worried it would end up out-of-round. Measuring with a bore gauge showed the race was still circular, however. When the inner bearing is dropped in place, it rotates smoothly, with no rocking (as would happen if it were out-of-round), so we’re golden!