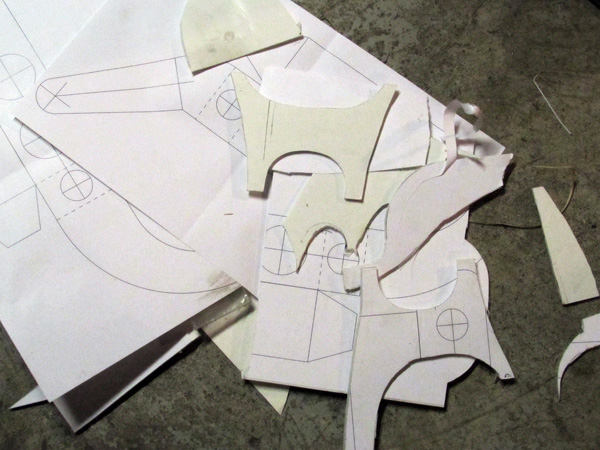

I continued heading down the path of welding a shock mount to my swingarm. I bought some 1/4″ steel plate. After about two dozen templates, I was about ready to start cutting.

I re-considered that tack. Even my best design was going to be ridiculously heavy and ugly. (You can see the partially cut plate in the lower right of the photo below) It was clearly going to look like a backyard bodge. So I went back to my collection of suspension linkages…

And began one more attempt at figuring out how I might attach a workable progressive linkage.

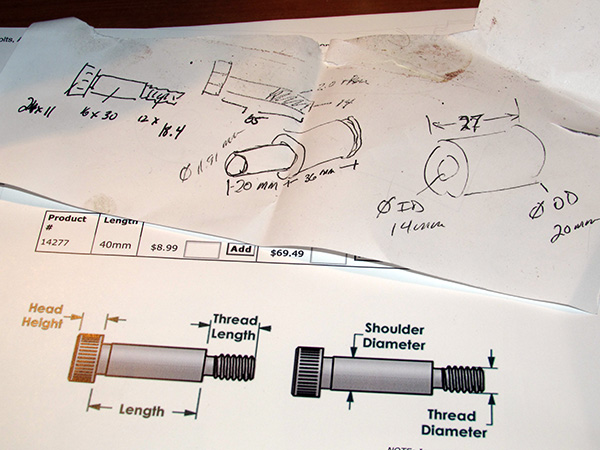

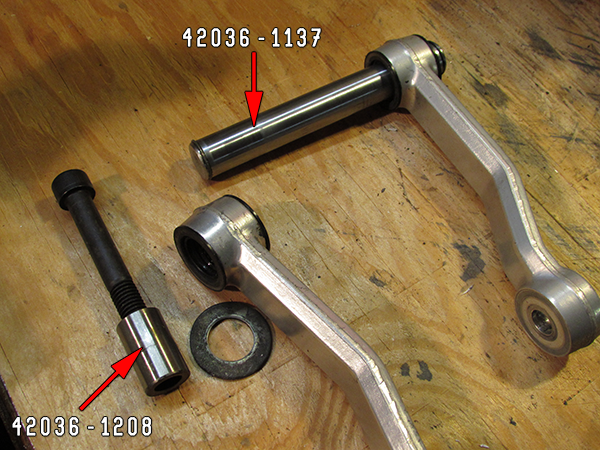

I’d bought two fancy, alloy Ninja 900 dogbones, but the big, solid shaft the they pivoted on clearly wasn’t going to do me any good. There were a couple of online vendors whose websites made my investigation a thousand times more fruitful. At this pint I have to give mad props/a shout out/a jolly hip-hip-hooray to Partzilla.com. They not only list the full OEM part number for their online fiche catalog, but they also provide a clickable interchange list, which shows every other application where the manufacturer used that part. This is incredibly useful. I was feeling very proud of myself when I ferreted out that Kawasaki used the same needle bearing in my dogbones on about a jillion monoshock bikes, including the KL650, which could provide a more suitable race.

Bingo, just what I needed. I ordered one for $10 shipped, and thought I was well on my way to solving my problems.

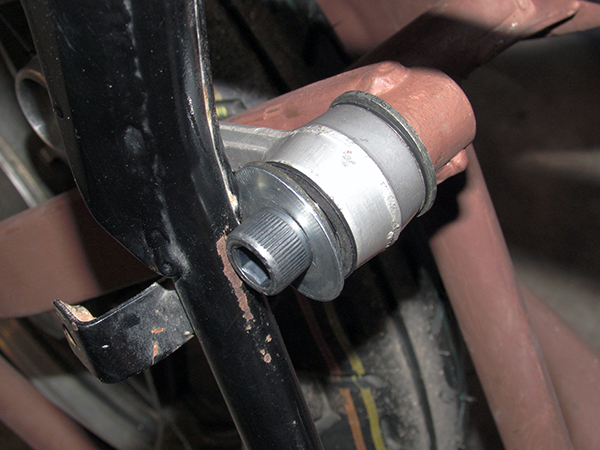

Oops, a little unforeseen problem there. My thought at the time was, see, these are problems you can only discover by actually trying. Or, as my father-in-law used to say, “In theory, there’s no difference between theory and practice. In practice, there is.” Trying to overcome the clearance issue had me thinking again about welding the swingarm, or cutting and welding the frame…which quickly brought me to the same conclusion that I’d arrived at previously: a linkage arrangement is too involved for the scope and budget of this project. The idea is to see what I can make fit together cheaply and easily, not to design a clean-sheet swingarm or frame. I needed to find a solution that worked with the parts I had.

I was frankly feeling very discouraged. I doubted whether this bike would ever come together, and if it did, whether it would be functional and attractive enough for me to be at all proud of. I was feeling very much the shadetree hack I am. I really didn’t want to end up with some embarassing, awkward, unsafe Trailer Park Bubba special.

I wanted to sweep out my 100 sq. ft. workspace. The bike was ready to roll around except for the rear damper, so I quickly grabbed a length of aluminum square stock and drilled a couple of hole in it. I mounted it like a drag strut; the bike would be a hardtail temporarily, but I could move it more easily.

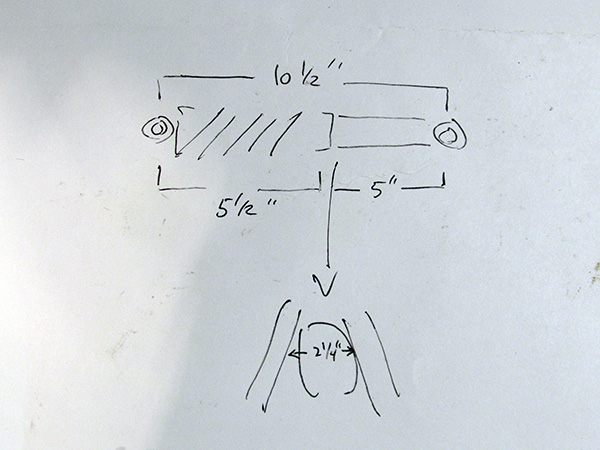

I suddenly realized that I had accomplished almost everything I needed to have a rolling chassis, which I’ve set up as my first major milestone in the build. I was just one damper unit short of having a working design for the wheels and suspension. I just needed to find the right damper. Forget linkages or mods, just find the right shock. I sketched out the dimensional limitations.

None of the three shocks I’d purchased for this project were going to work. I looked again at used OE shocks, mountain bike air shocks, and cheap Chinese mini-moto shocks. Here’s where I have also give HUGE credit to an Ebay salvage business that made further hunting possible: Pinwall Cycle Parts. Every damper unit they sell is photographed on a tape measure, to show you the dimensions. Looking through their inventory, a single Harley FLH air shock might almost fit, but no. Same for a Honda VLX600 shock. Both are too wide to fit between the Bultaco frame’s narrow side rails.

I finally came to the one shock that will work: A Buell Blast 500 shock. It not only fits, but it is from a bike of similar size, weight, power, and usage. As with my bike, the Blast does not use a linkage. I had actually considered a Blast shock early on, but it’s totally non-adjustable and probably a bit over-sprung and under-damped. But at least it’s better durability and build quality that a useless Chinese replacement shock, which is my other option. They’re also cheap. I bought one off Ebay for $15, shipped. (Pinwall did not have a current auction for a Blast shock, or I would’ve bought from them. I don’t believe you should dance with one girl and take another home.) My shock will be here Thursday. We’ll see how it works.