I have had concerns about the the steering stem I originally modified for Bultakenstein being too thin-walled after machining. Some measuring, it turns out that my proposed modification for the A-D Special would remove about 25% of the thickness of the metal at the very bottom of the bearing contact. That made me a little nervous, and I started considering safer alternatives. An additional factor was that I cannot fit a welded steering stem and triple clamp unit into my lathe. (I had planned on using one at the local community college workshop, which is available to the public, but of course the lockdown for the rest of the school term squelched that.)

I decided to look again at suitable alternatives, this time one with a pressed-in stem, rather than a welded-in stem. For this I turned again to the incredibly useful Japanese Fork Diameter List and Japanese Steering Bearing List, which have been published various places on the web. (Thank you to whatever diligent soul put those together!)

A lot of Japanese bikes have 30mm ID x 54mm OD lower steering bearings. The Aermacchi requires 52mm OD bearing races, which is common among older European bikes (including Bultakenstein, for instance). I discovered that a few Kawasakis, including the original Z1/KZ900, used a somewhat unusual 30mm x 52mm lower bearing size — exactly what I needed to open up a lot more alternatives. I began culling the pool of bikes to those that had:

- 30 mm lower bearing ID

- 37 mm fork tubes

- A pressed-in, not welded steering stem, and preferably all steel (pressing out the stem tends to gall alloy).

One candidate was the GS500. Googling information on this bike, I ran across a GS500 fork-swap article that included this photo, of a Katana 600/750 front end installed in a GS500 frame:

See the required spacers? The author had the same issue I had. This got my attention: the stock GS500 steering stem was shorter, — which would be what I need! How much shorter, though? The author even included measurements, and it looked as though the GS500 would be very close to the correct length for my Aermacchi frame, without any spacers. Very promising!

I went out on Ebay and found out that some GS500 stems are pressed, and some are welded. I found one cheaply that included the top triple clamp, but was welded, and another that was pressed in, but without the top clamp. I ordered both, along with a set of Z1 steering bearings (the bottom bearing is not available separately from the usual industrial bearing vendors). After all the parts arrived, I was very excited to discover that the GS500 stem is a perfect fit — within 3mm of the optimal length! Here it is compared to my current GS700E steering stem:

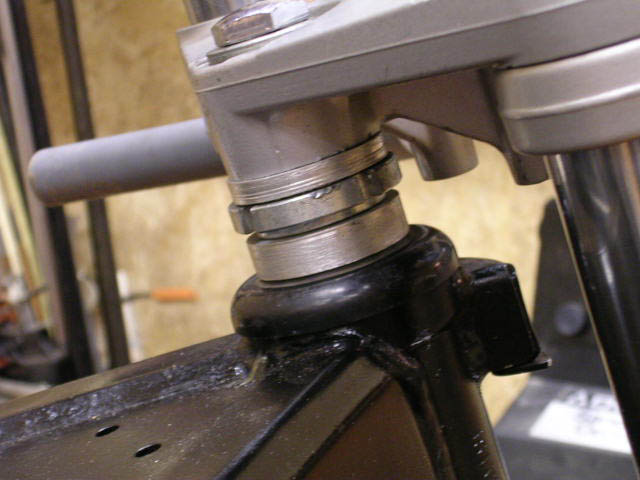

Swapping out the lower bearing is all that’s needed for it to bolt up to my frame — without any machine work! Since I had no need to press out the stem, I decided to hold the pressed-in triple clamp in reserve and simply use the welded one. I cut off the old bearing, pressed the correct one on, swapped out the lower race in the frame for its match, and bolted it all into place.

Here’s where things got weird. When I tried to insert the fork tubes, they didn’t line up. The top triple clamp could either fit the fork tubes, or the steering stem, but not both.

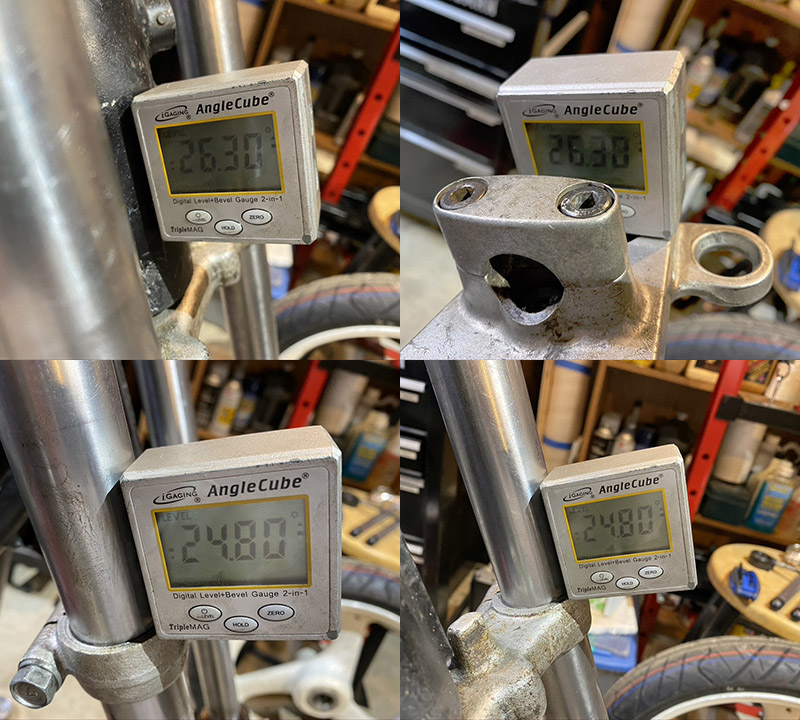

I got out my angle cube to verify what I was seeing:

Either this steering stem is bent 1.5°, or the bottom steering stem itself is tweaked. In any case, this is from a bike that had a very unhealthy front-end collision. I assembled the forks and top clamp onto the other steering stem/lower clamp unit and, sure enough, everything bolted right up.

I contacted the Ebay vendor, and since the purchase had included a top clamp that was still good, and which I still needed, we settled on a 50% refund. Unfortunately, there’s no way I can get the lower bearing off the bad stem without buggering it up, so I had to fork out another $36 for a second All Balls Z1 bearing set. (I will soon have a lifetime supply of 30mm x 48mm tapered roller bearings.) However, my net cost for all the additional parts I bought, including the replacement set of bearings, is just shy of $75 — still less than a machine shop would have charged me to turn the GS700 stem as I’d planned. Furthermore, the GS500 fork spacing now matches the GS1000 axle spacers I bought, so the front wheel bolted up without having to fabricate anything there, either. Another win! Thank you, Suzuki engineers. Of course, the nifty steering stop plate I made won’t work, so I will have to fabricate something else but, overall, I’m tickled to have the front end pretty much sorted.