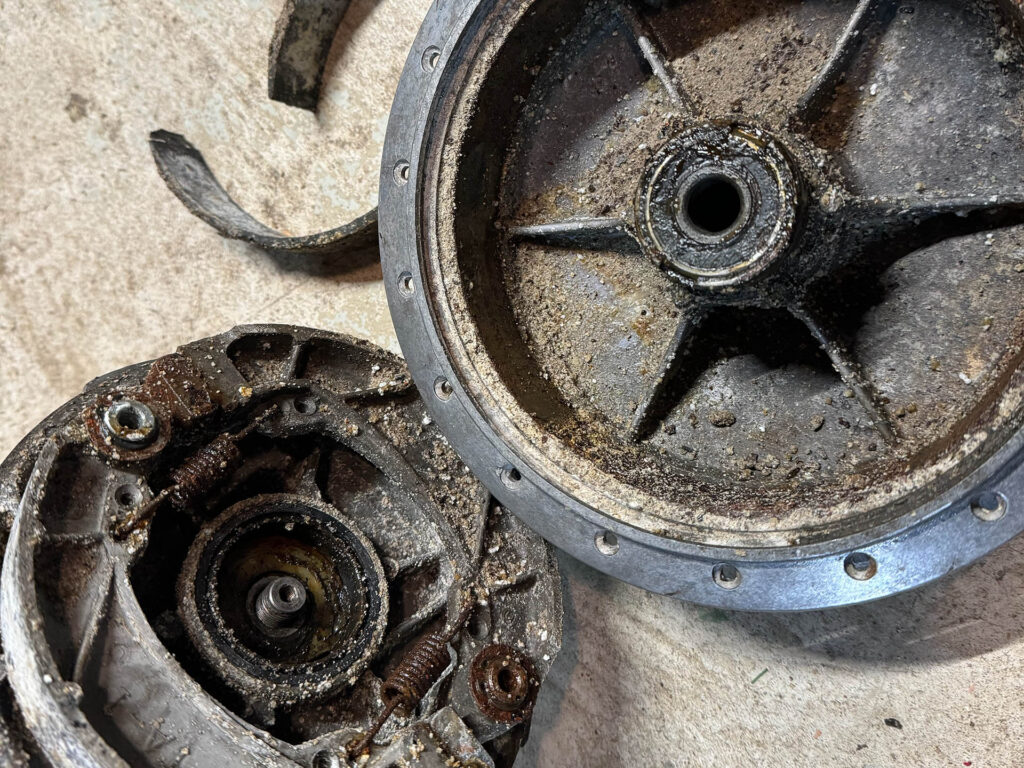

Well, it took me about two hours of effort to get the Bridgestone 175 front brake apart, but I was (reasonably) successful. The culprit I had been fighting against was sand. Not just a little coating of trail dust, but thick, gritty sand like you’d find on a beach or riverbed, and plenty of it. This bike obviously lived a hard life. Everything was so choked up with sand that when I did manage to get the brake plate off, the brake linings stayed behind, wedged against the drum. I had only been able to separate the parts after breaking the friction material free from the backing shoes.

Now that I’ve I stripped everything down, I’m not really sure how many of these parts are worth keeping. Used Bridgestone brake parts are pretty cheap, and NOS stock is still available for most parts.

Full disclosure: In the interest of transparency, I won’t hide my stupid moves. I know that you NEVER pry on cast aluminum. In fact, before I started this I said to myself, “Don’t be stupid and try to pry this open.” But this thing fought me every inch of the way, and after a while, I was running out of things to try. Once the brake panel had shifted enough to open up a gap, the siren song of an effective solution was too tempting to resist. I started prying the halves apart. And, frankly, it was the thing that finally worked. But, as you can probably guess, not without some boneheaded damage. Furthermore, both of my little oopsies happened to the brake panel, not the hub, which is probably junk and already slated for replacement.

In the end, the external bit can be dressed out so that it’s unnoticeable. The chip out of the inner rim will be hidden and have a negligible effect on function. But it furthers the case for just chucking this into the scrap bin and getting another one.