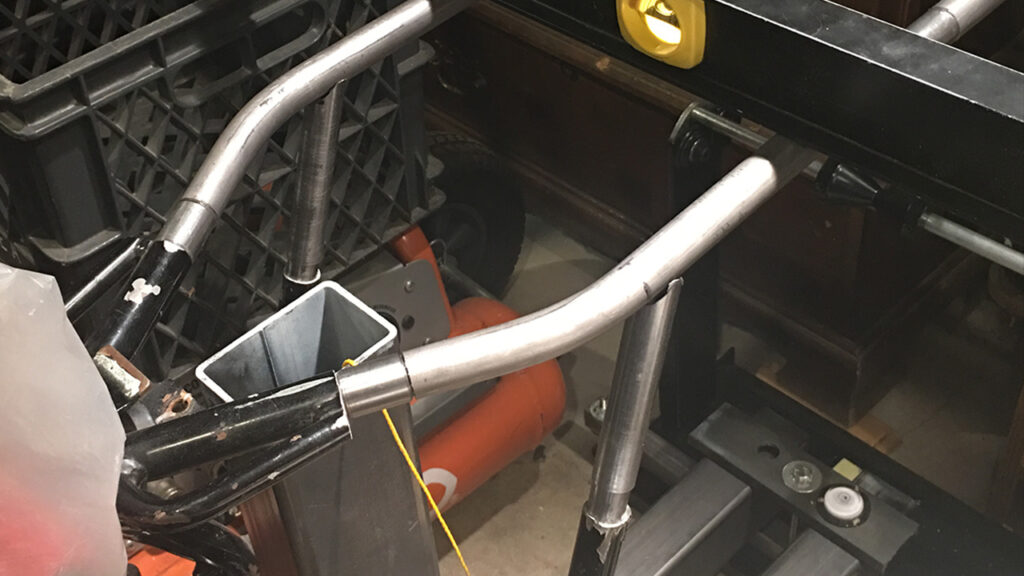

I used the new notcher and, in the words of Colonel Cochran, “the damn thing acted like it had good sense.” I was going to use it in my drill press, but the instructions suggested that a variable speed drill was actually preferable, since it could be slowed down below the minimum speed of my press. Even though I was cutting through .120 wall tubing, it was a comparative breeze, especially compared to how I was trying to do it.

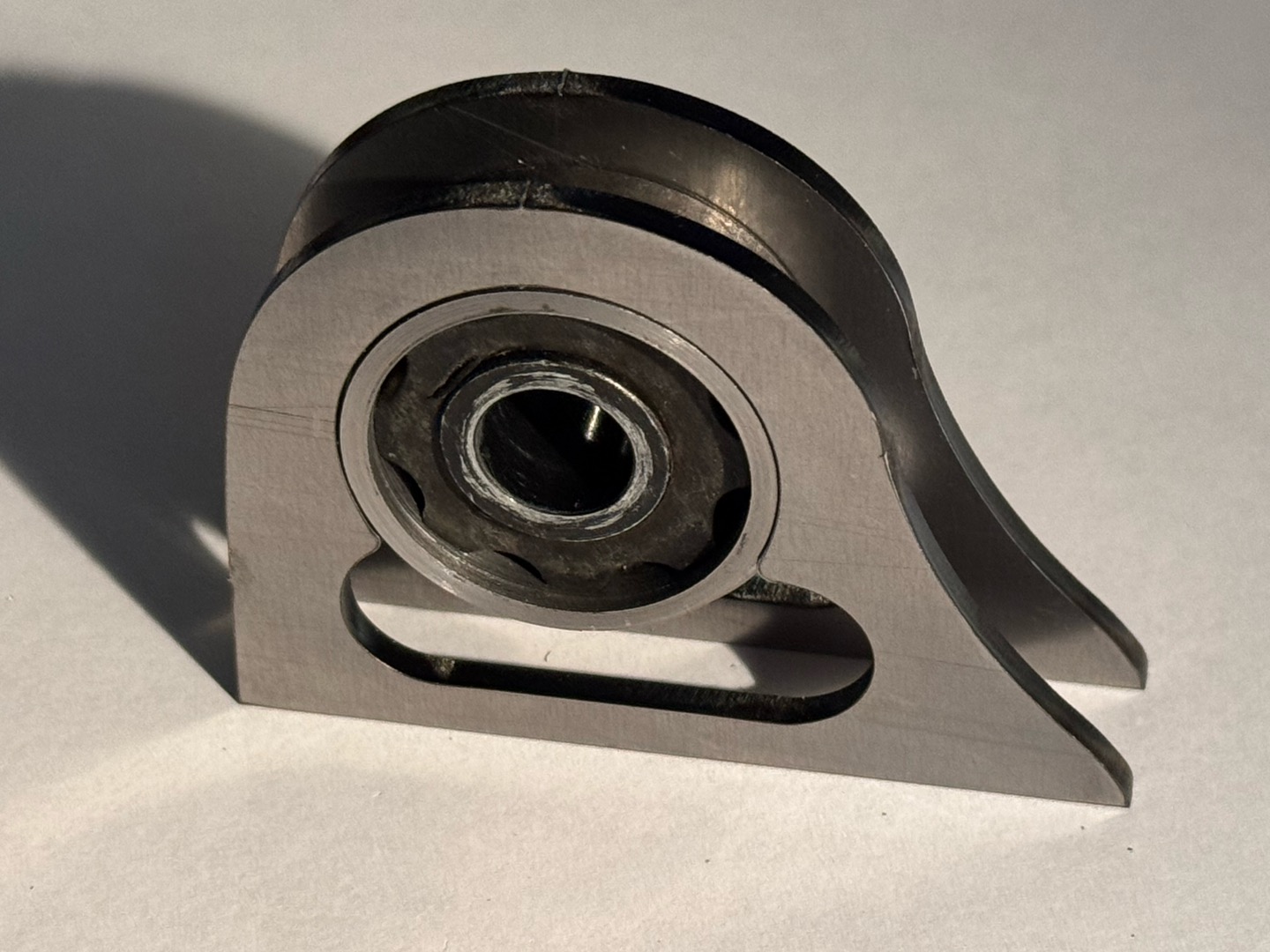

The fishmouths in the pictures show the raw cut. They need a bit of filing to fit up nice and snug, but that’s to be expected. The carriage on the notcher for the tubing should probably be shimmed a small amount, as the curves were not perfectly centered.

I have an appointment to drop the frame off at my neighborhood welder next Thursday; I still need to make up some plates and gussets by then.