To aid in fabricating my engine mounts, I attempted to order a press brake for my hydraulic shop press. When I learned that it was backordered indefinitely, I had time to consider alternatives. I decided to pivot and go with a bolted-up alloy arrangement, rather than the folded steel box I had imagined previously.

I don’t have a chop saw or band saw, and I wasn’t looking forward to hacksawing through 8 inches of 1/2″ thick 6061 aluminum. Several people online had good results with circular saw blades designed specifically designed for cutting aluminum. I was skeptical; as a rule, cutting metal with a saw designed for wood is a no-no. However, I decided that for $20, it was worth a shot. Even if I just able to get a good, straight, perpendicular score across the metal, it would help me cut straight with the hacksaw.

I swapped out the blade in my sliding miter saw and used the adjustable depth stop to make a series of approx. 1/8″ deep passes. That was probably conservative. It cut effortlessly—no bogging, no burning, just plenty of little chips flying out the back of the saw. The resulting cut was really clean. I’m really surprised how well it works. I should have tried this long ago.

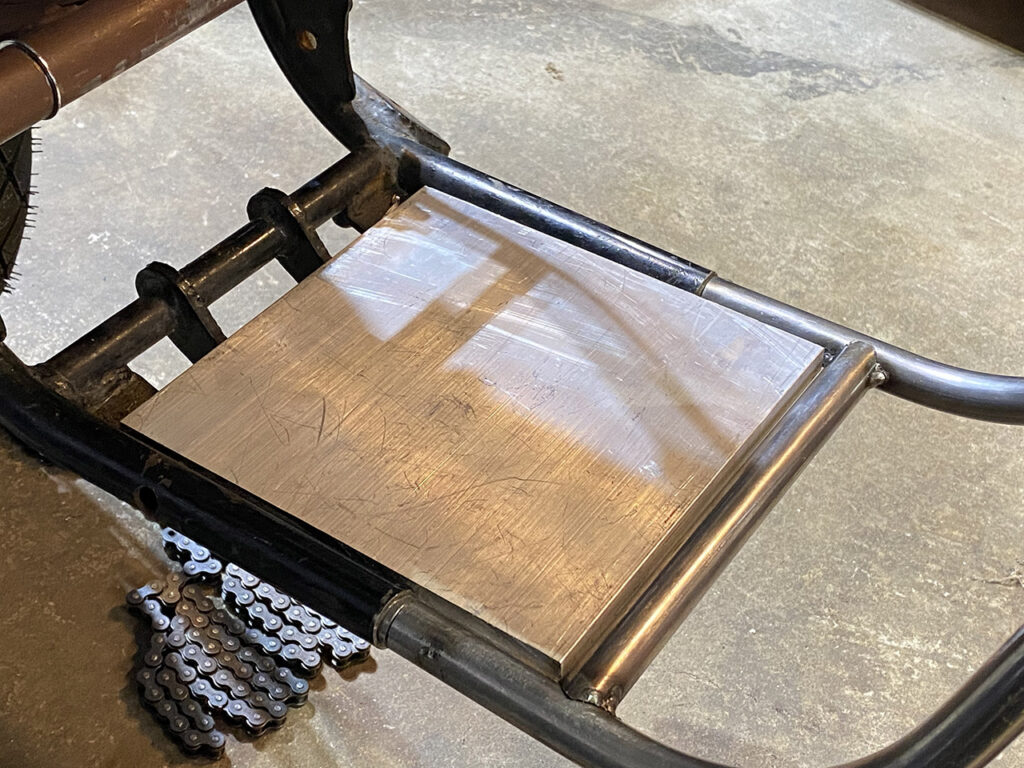

Here’s the base plate, ready to drill and bolt into the frame.

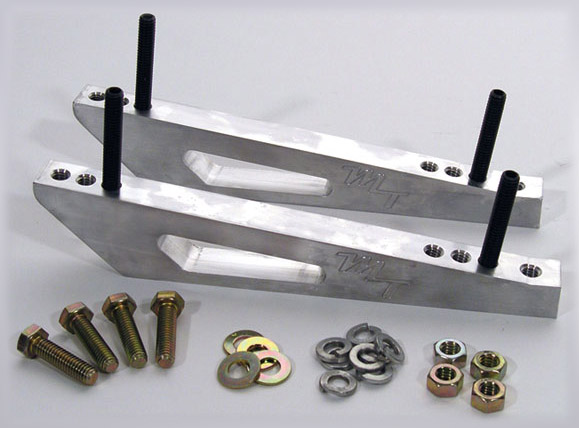

Bolted to this will be two angled vertical plates that will, in turn, bolt to the engine. I have 7/8″ thick 6061 arriving today. They will look similar to this pair of commercial kart engine mounts—only lots cruder, most likely.