Man-oh-man, I’m well and truly into it now. I just keep digging this hole deeper. This is my first time inside a commercial/industrial type engine. It’s very simple, which is good, but I’m unfamiliar with a lot of the engineering. I’m a motorcycle guy, and a lot of this seems more car-like than bike-like.

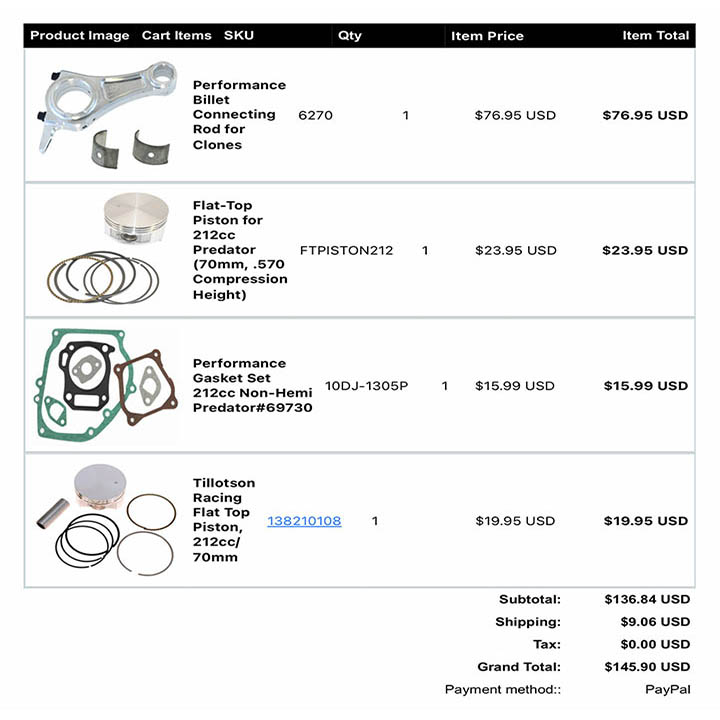

I purchased a new high-performance billet connecting rod, a gasket set, a couple of different pistons. I really only needed the rod, but because the oddball LCT engine uses a larger, non-standard wrist pin, I had to order a standard-spec, flat-top 70mm piston to fit the GX clone rod. I wasn’t sure if I needed a compression height of .550″ or .570″, and from the website, I didn’t think the .570 piston came with a wrist pin (actually, it did). So, I simply ordered two pistons. They were cheap enough, after all. However, these parts ended up costing me a good deal more than the $99 I paid for the entire engine.