I gave up on installing a true jackshaft in favor of a single idler sprocket. There simply isn’t room for it without extensively modifying (almost completely re-engineering) the swingarm pivot. Beyond that, the way the engine sits in the frame, I would not be able to offset it far enough to run on the inner sprocket. In the end, none of that is necessary. Given this bike’s meager power and suspension travel, this will work fine.

Funny, but with most builds, the challenge is trying to get the sprockets in line. With this one, I can’t avoid it. As I said before, The Bride keeps telling me what it wants to be.

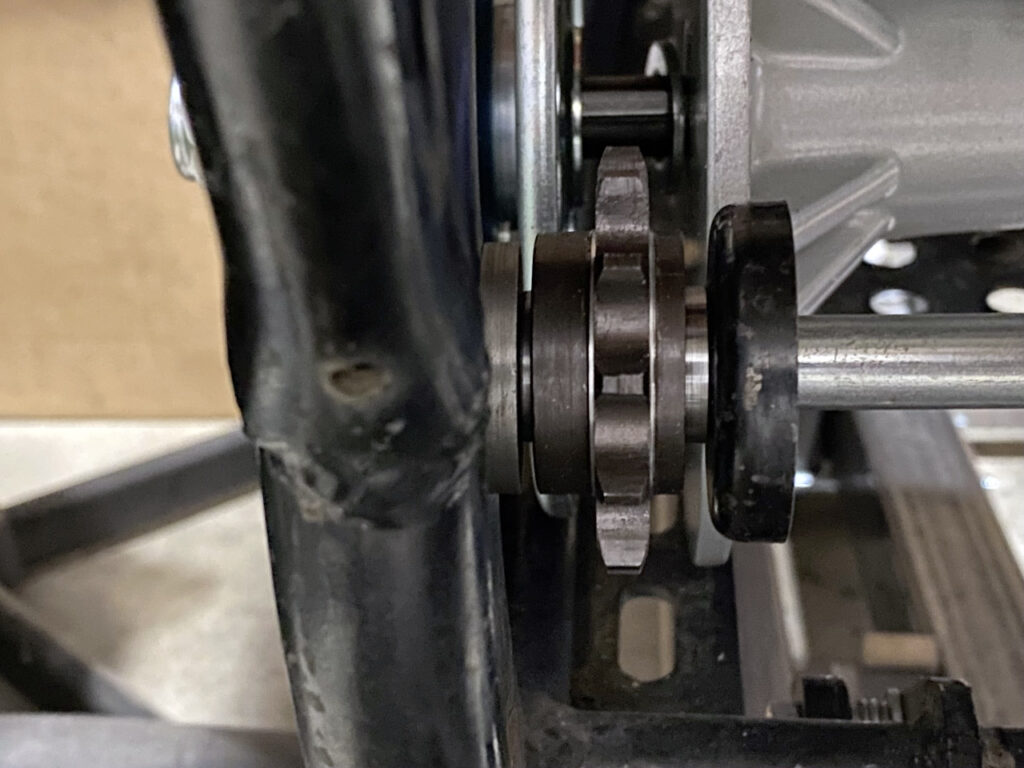

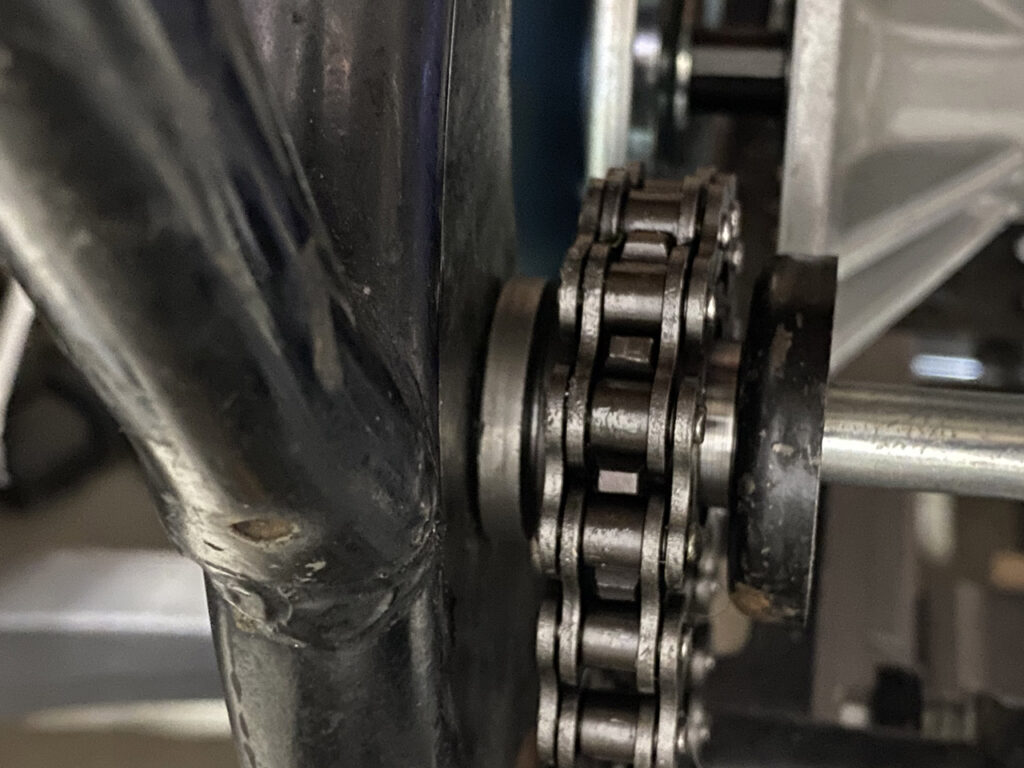

I bought a single idler sprocket made for #40 industrial chain. Since it needs to fit narrower 420 drive chain, I put it in the lathe and took 0.8mm (0.31″) off each side of the sprocket — visible as the shiny silver ring on either side of the sprocket teeth. I then turned two spacers of the same width, with a small enough OD to fit within the outer shoulder and butt up against the inner bearing race properly. As you can see, the sprocket has a shorter shoulder on one side, but I wanted to leave plenty of room for the width of the chain itself to clear everything around it.

The frame is still in the jig, so I can accurately measure the chain offset from the centerline. My next steps will be to:

- modify the rear sprocket carrier to match the chain offset,

- shorten the drive side of the swingarm pivot to make room for the idler and install the swingarm,

- make up the proper width rear axle spacers to center the rear wheel in the frame (important to calculate in the jig because the swingarm will remain offset slightly),

- mount the engine so that the drive sprocket on the torque converter lines up with the other two sprockets.

At that point, I can unbolt it from the jig and make a rolling chassis out of it. My wife will be very happy about this, since it will stop taking up prime real estate in the middle of the basement.