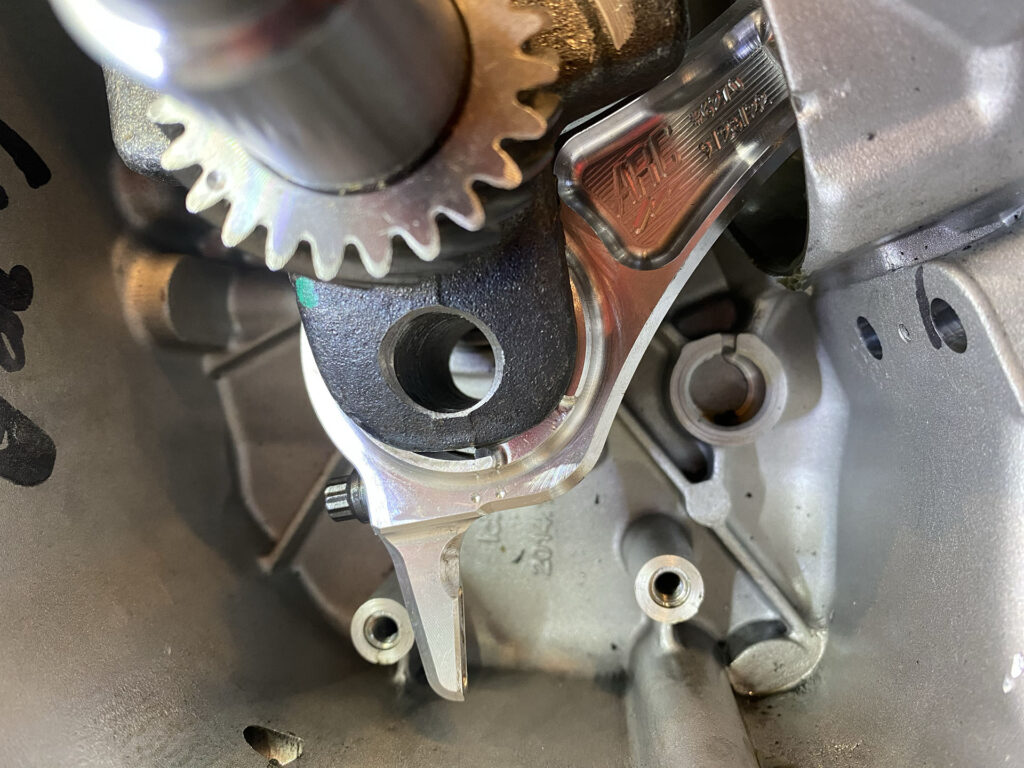

An internet commenter encouraged me to substitute something better than the stock crank, rather than go back to using stock engine innards. I decided that was the right move, so I ordered a GX clone crank from OMB Warehouse for about $50 (including crank shims that I don’t think I’ll need). Not only will I now be able to use the ARC billet rod and Tillotson flat-top piston, but I won’t have to take extra shop time to fabricate the bolt-on replacement oil dipper I planned to make.

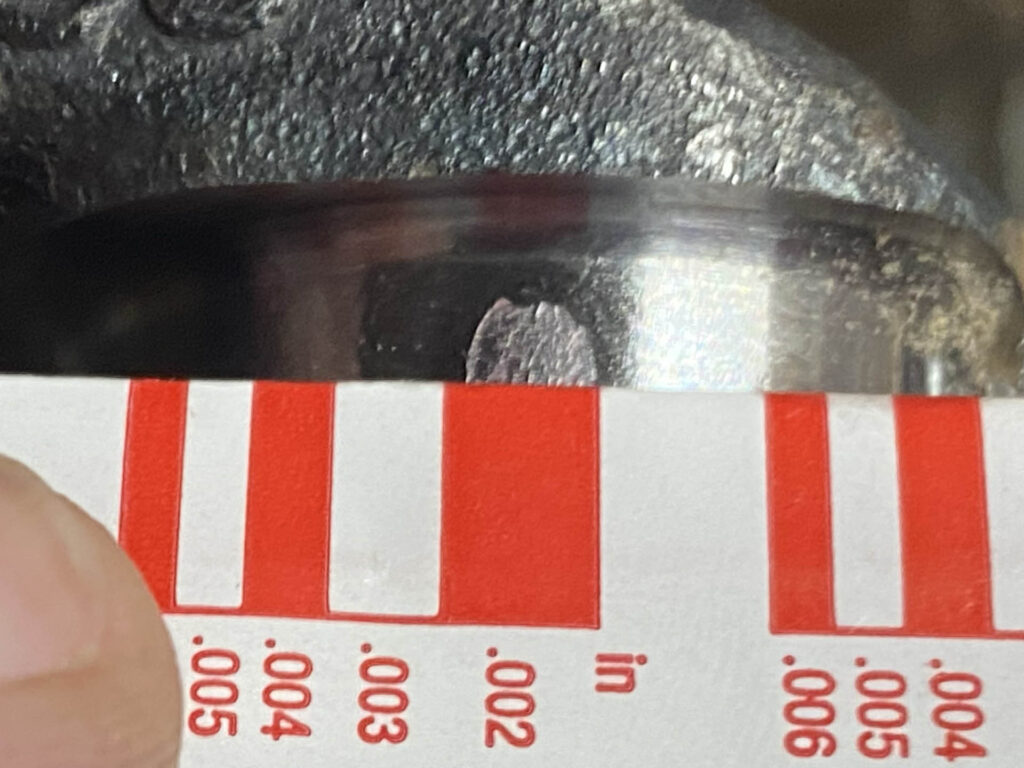

After too many weeks without making progress, I was able to get into the shop and check out my new crank. The Plastigauge now reads between .002″ and .003″ — right in the sweet spot.

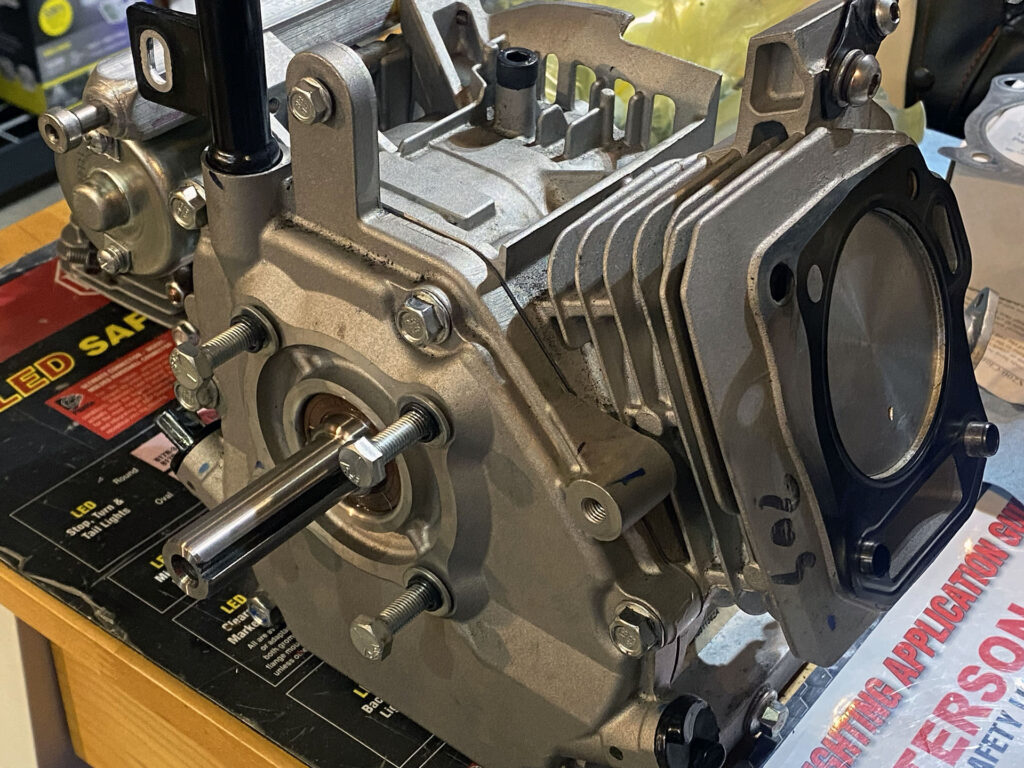

I verified that the crank mains fit the crank bearings in the cases, checked the ring gaps, and assembled the crankcase, torquing everything to spec. It’s worth the extra expense to know that I’ve got suitably robust components inside and probably won’t have to open it back up again anytime soon.