After measuring a bunch of times, I conjured up the gumption to cut into the swingarm. I went slow, with a hack saw, and actually managed to make a perpendicular cut. I assembled it and it fits! The part I cut off the left still needs to be welded to the right side, so I can use the stock width bearing bushing. In this photo, I just slipped a shiny washer in between the two pieces to replace the width of the hacksaw blade.

I’ve ordered a larger diameter piece of DOM tubing to use as a reinforcing sleeve over this joint. I only have a 125 Amp Titanium flux-core welder, so I might take it to my local welding shop. I haven’t decided yet.

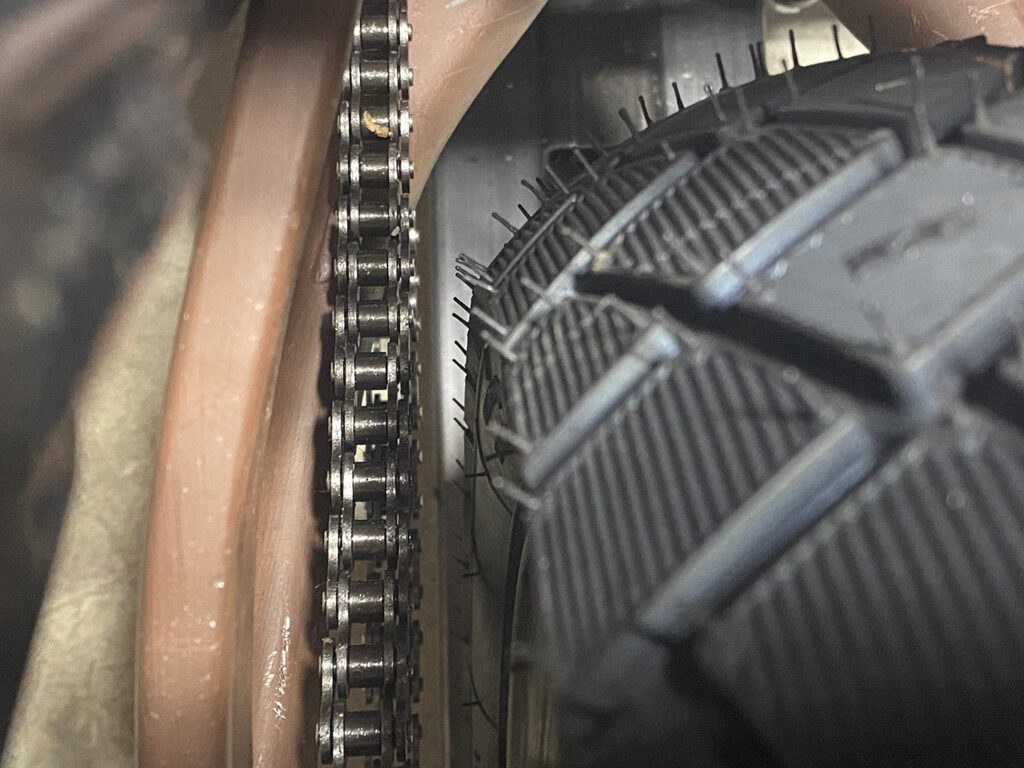

Once I had the swingarm positively located, I made up spacers to center the rear wheel. You can see from these photos why I had to do the lathe work on the sprocket carrier. Even with my mods, there is no room to spare!

The spacer on the other side is a temporary “dummy.” Eventually I will need to fabricate a rear caliper hanger that will occupy the extra space on this side of the axle.

There’s still a lot to do, including all those little things you don’t think about, such as pins for the snail adjusters. However it feels really good to have the swingarm in position and rear wheel centered. Looking at the bike with the rear tire on, I have to say I’m pleased with how it looks. It makes me eager for more progress.