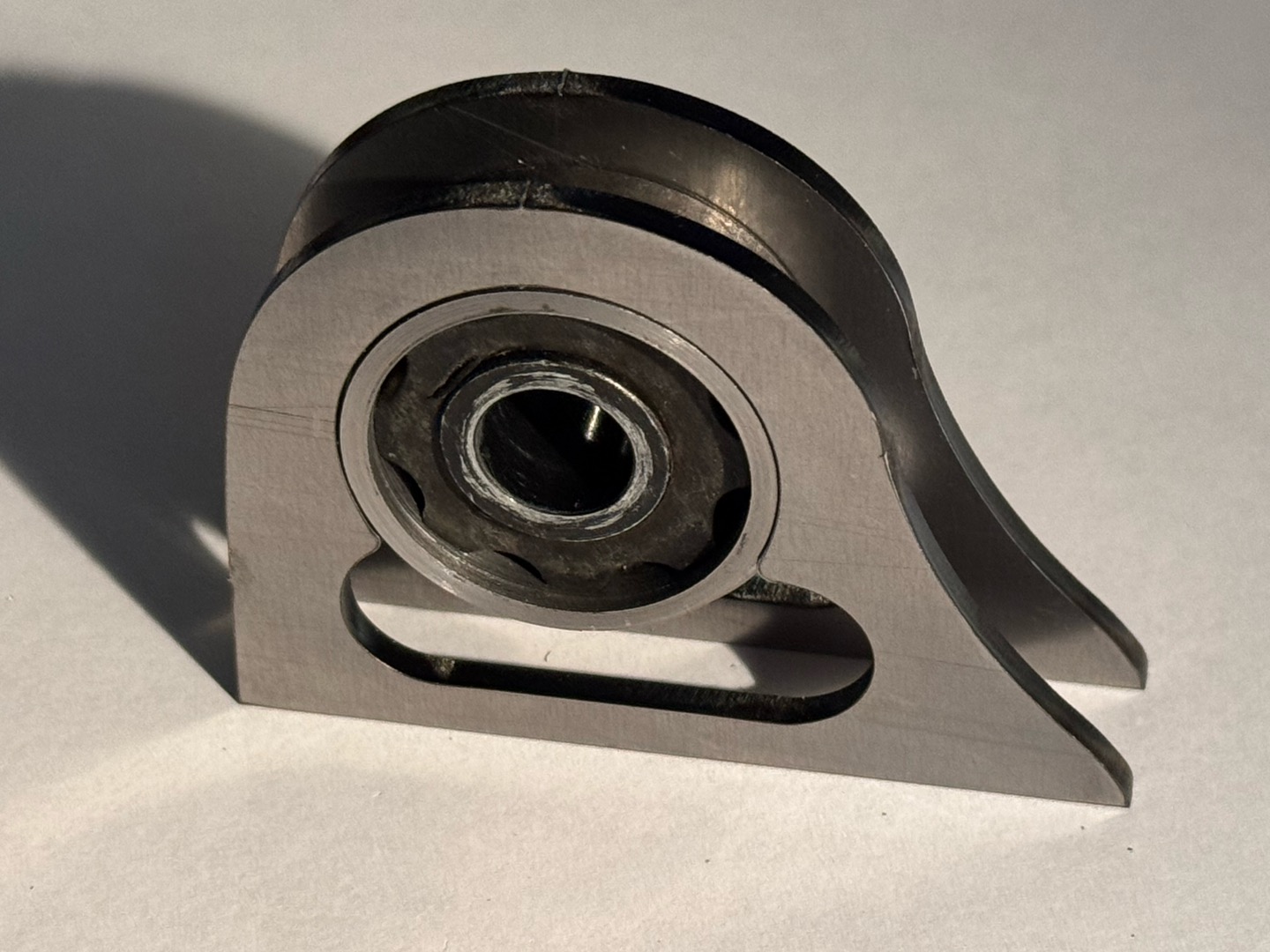

Okay, refer back to the photo of the crappy spacers I made about a month ago. Now, here are the new spacers I made on that lathe last night.

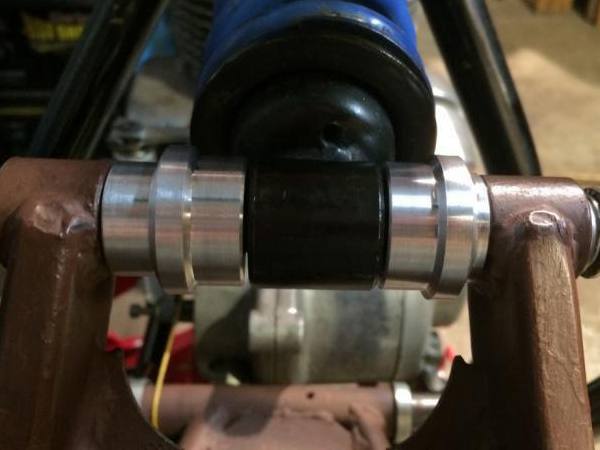

Notice how the inner diameter matches the end of the shock and the outer diameter matches the swingarm bosses. And they’re the proper width, with no slop. Suddenly, stuff like that is sooo easy! The raised ridges between the two diameters are purely aesthetic. The swingarm is offset in the frame a bit, and I thought they made it look more as though they were intentionally different lengths. The more complex shape was also great practice to accurately duplicate all the various dimensions on two matching parts. And the beveled sides were a good excuse to try out the compound slide.

Having the right tools makes all the difference in the world.