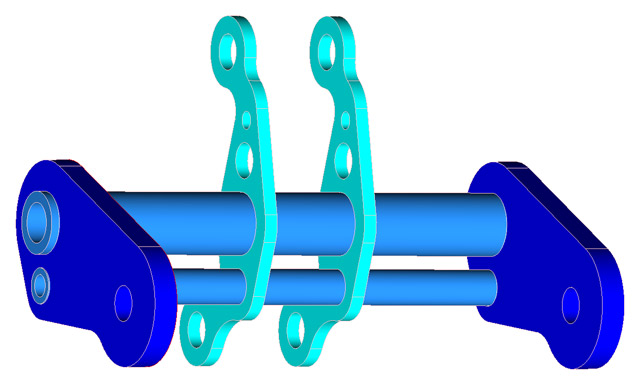

Here we have a rear carrier assembly I designed that would tie the frame, rear engine mounts and swingarm pivot all together.

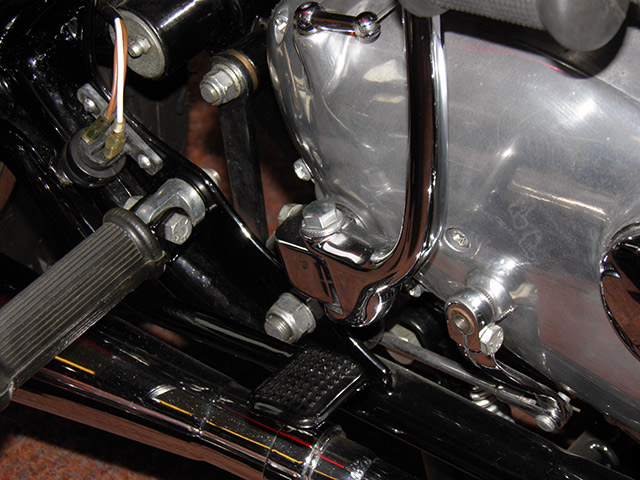

I thought the second, smaller tube at the bottom, though probably overkill, strength-wise, would reduce the chance of distortion due to suspension loads (although probably theoretically stronger than the swingarm itself). More practically, it’s an easy way to positively align the the swingarm plates and motor mount while welding. The lower tube was also intended to have a third function, acting as the mounting tube for a crossover shaft to adapt my early right-shift crankcases to a modern left-side shift configuration. I spent time studying the BSA/Norton P92 prototype’s arrangement (in the photo below) when I was at the British National Motorcycle Museum this spring.

After going through all the effort to create that CAD drawing, I realized that my twin-tube crossmember design has one fatal flaw — the lower tube/shift shaft housing would run right through the lower drive chain path. Oops. I’ll have to re-think this. Perhaps the second tube could sit to the rear, between the main tube and the swingarm pivot.

Fortunately, it’s a whole lot easier (not to mention cheaper!) to find that out now. That’s why I’m spending so much time and effort in the sketching/planning stage, trying to catch all these issues.