Well, it’s official, I am complete and utter dolt.

The Buell Blast shock arrived. I headed excitedly to the workbench, eager to see my suspension ordeal finally end in success. Well, there was a minor issue of 10mm bolt eyes on the shock and a 12mm bolt holes in the swingarm, but it went in fine.

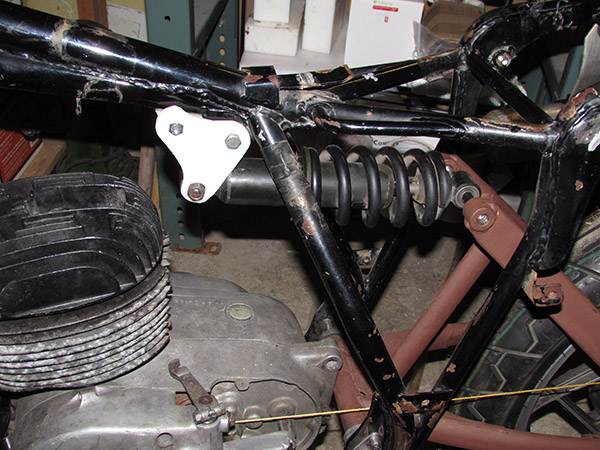

Looks like it fits in there fine, doesn’t it? Yes, it fits…but it doesn’t work!

I took it off the stand and let it stand on its own on the shop floor…

And then got out a string to check chain clearance.

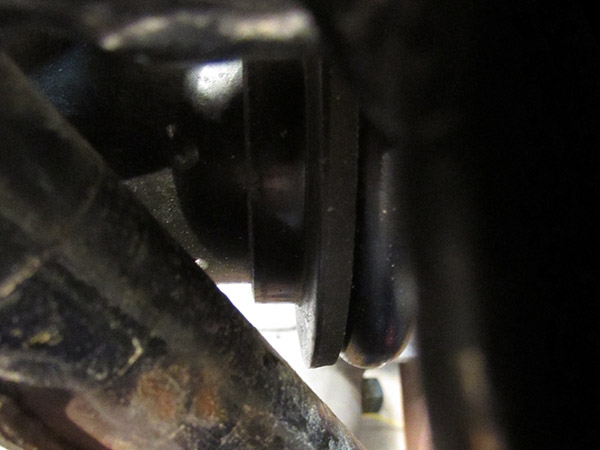

Above the swingarm, clearance at the pivot was pretty close with the shock at full extension. Definitely needs some sort of plastic rub block over the swingarm, but it’s probably workable, and as good as I can get because…

The frame tubes at the rear of the fuel tank prevent me from locating the shock any further forward in the frame.

That’s when I realized how stupid I am. I wanted to check and see how much the string moved when I sat on the bike and compressed the shock. I swung a leg over and bounced my weight a few times on the back of the frame.

And…nothing. The only movement was from the flexing of my temporary plastic brackets. The bike was still a hardtail; the shock didn’t give at all.

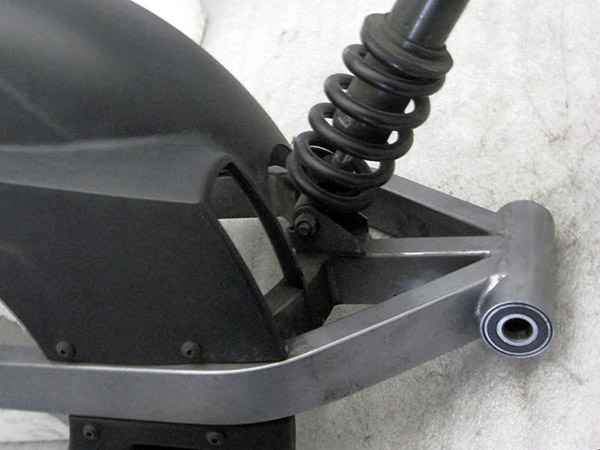

It should have been obvious to me, if I’d done a little more thinking. Look at a Blast swingarm:

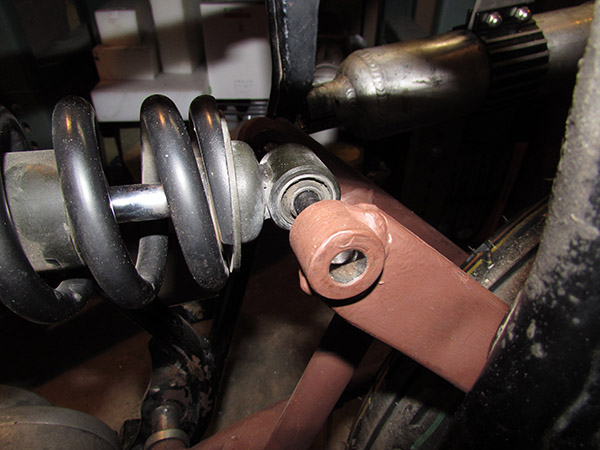

The bottom shock mount is only about half the distance from the swingarm pivot compared to my Yamaha monocross swingarm. I have no idea how the overall swingarm length and wheel travel compare to mine, but the shock lever arm to wheel arm ratio on the Blast is definitely a whole lot greater than mine. The spring rate could probably be twice what I need. Just out of curiosity, I pulled the Raptor ATV shock off the shelf and bolted that in as solidly as I could manage. Same thing: no give at all, even with me putting all my weight on the very back of the seat loop. What about my original XR80R shock? I fitted that loosely to the bike and sat on the seat rails. A very appropriate 1/2″ –3/4″ of sag. And when I bounced up and down, it actually moved enough that I could see the damper compressing slightly. It felt…about like a normal bike suspension.

I feel like a moron, or at least incredibly naive. I knew that I probably wouldn’t get truly optimum spring and damping specs from a shock randomly pulled off another bike, but I figured anything without a linkage would be somewhere close enough to work. You know. “Eh, she rides a bit on the stiff side right now, but I’ll sort that out somewhere down the line…” I’ve chuckled at guys who hook up fat-springed shocks designed for linkages straight to the swingarm, and wondered why there was zero suspension travel. I guess I need to laugh at myself now.

Buell Blast shock at top, XR80R shock below.

So, isn’t this a hell of a thing. Four shocks so far, and still not one good option. The one shock I’ve found with a workable length AND a reasonable spring rate has zero damping to speak of, no height adjustment, no preload adjustment, is made out of tin foil and pot metal, and has a rather inconvenient clevis mount at one end.

Dang, this seemed like such a simple idea at first.

This sort of thing was all I wanted to do. How hard could it be?

I am a bit stymied and unsure how to proceed. Perhaps the frame, swingarm, or both needs to be altered after all. Of course, if I take that plunge, all sorts of different paths present themselves. Enough to paralyze me with options. For example, I noticed how the clevis end of the XR80R shock would easily bolt over one of the mounting bosses on either side of the YZ swingarm…

Which makes me think of bolting twin shocks on either side of the downtube, like this…

…or this…

At this point, who knows what direction I should take. Someone suggested that I swap the smaller XR80 spring onto the Blast shock body. I assumed that the XR80 spring wouldn’t fit, but looking more closely, that’s a possibility I’ll look into.