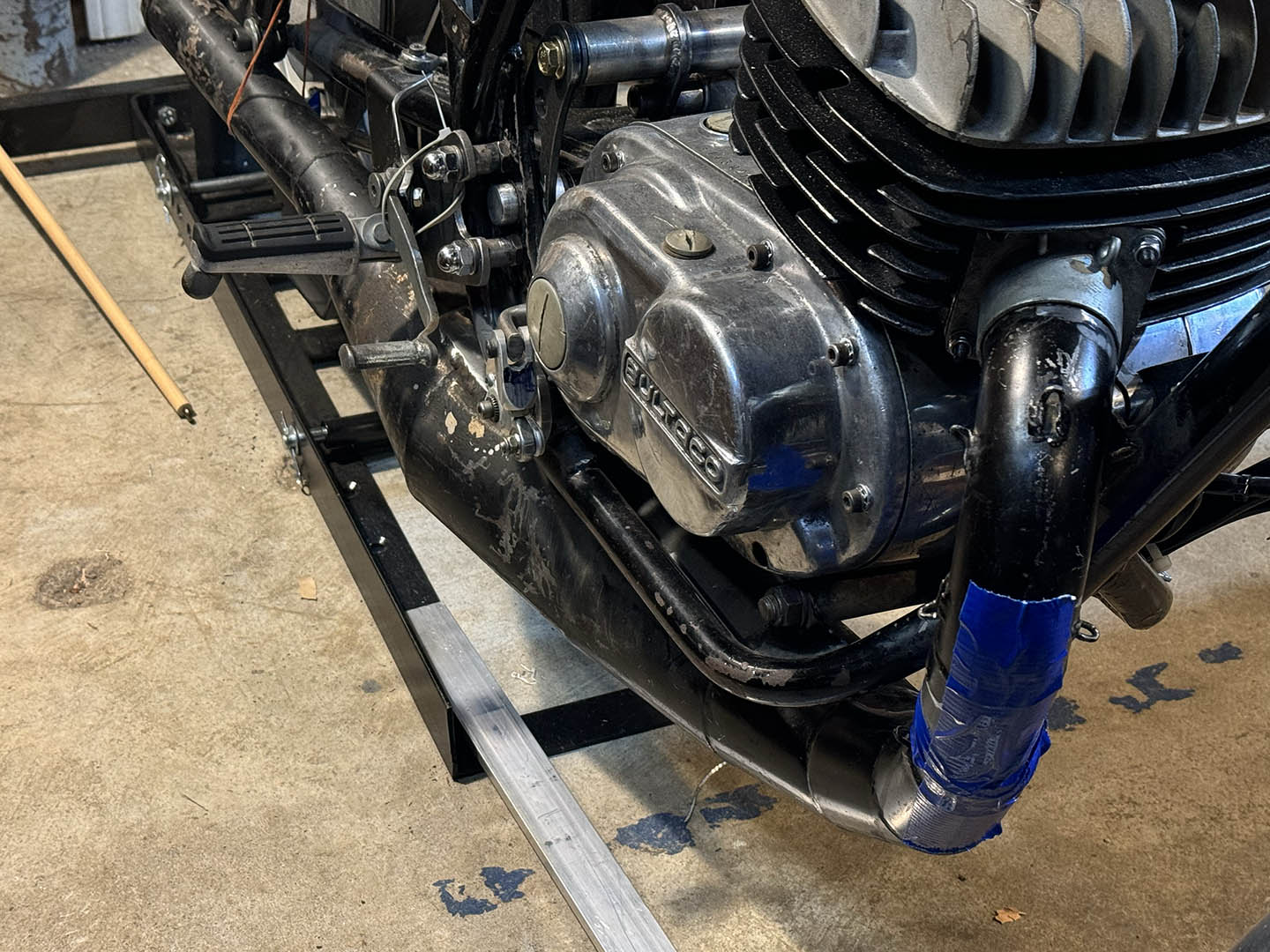

I’ve been suffering from a chronic lack of motivation on this project for a while now. To be frank, I’ve been somewhat depressed about how unprofessional it’s turning out to be. I even contemplated throwing in the towel and just parting it out again. But this morning before work, I decided to stop whining about not having the proper tools and instead get busy actually making SOMETHING, crappy or not.

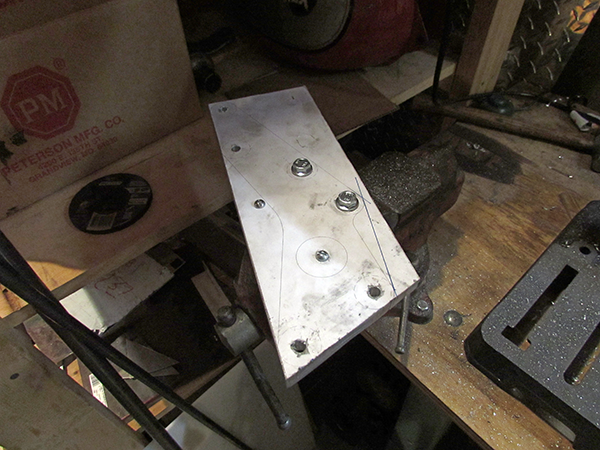

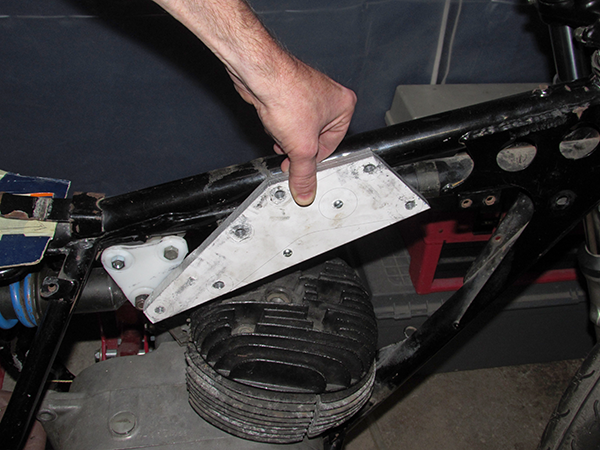

I had previously sketched out front shock mounting plates that are designed to attach to both backbone tubes, in order to (hopefully) feed the suspension stresses as directly as possible into the heaviest, most central of the frame. I had also purchased two 12″ pieces of 1/4″ x 4″ aluminum bar. This morning I started fabricating them. I attached my paper template to one using my usual method, spray adhesive. I then drilled and tapped two holes through both bars so I could lock them together with two cheap #10 x 1/2″ machine screws (I didn’t bother with metric screws, as these are temporarily screwed into material what will eventually be scrapped). I then drilled out the mounting holes (fairly accurately this time! woohoo!). By locking the two plates together, I’m assured that despite my less-than-precise fabrication methods, the bolt holes will be aligned, and the outer shapes will match — even though the outside contour isn’t a precision shape; it just has to hold the bolts and be strong enough not to flex or crack.

Using two M8 bolts in various holes to hold it in the lathe, I used a power saw to start cutting out the basic shape. At first I used my small Skil sabre saw, which made for slow going, so I hesitantly switched to my larger reciprocating saw (HF cheapie, but with a nice Lenox blade). I expected it to just chatter and jutter all over the place, but it actually cut fairly smoothly and accurately, and remarkably left a smoother edge than the sabre saw.

When I get done shaping it, I will bolt a spacer block between the two lowest bolt holes to keep the sides aligned, then use the plates as patterns to drill starter holes in the frame tubes from both sides. I will then be able to enlarge them to 5/8″ dia. and slide 4 properly-cut sections of 5/8″ x .120 DOM through the frame. I will MIG weld them in place, then use M8 through-bolts and nuts to attach the plates. (The ID of the bung tubing I’ve selected is a nice slip-fit for M8 bolts.) One of the reasons I am doing it this way is for a non-lethal failure mode: if my amateur welds break, the bungs will remain captured and totally functional, except for a little side-to-side movement and potential deformation of the frame holes.