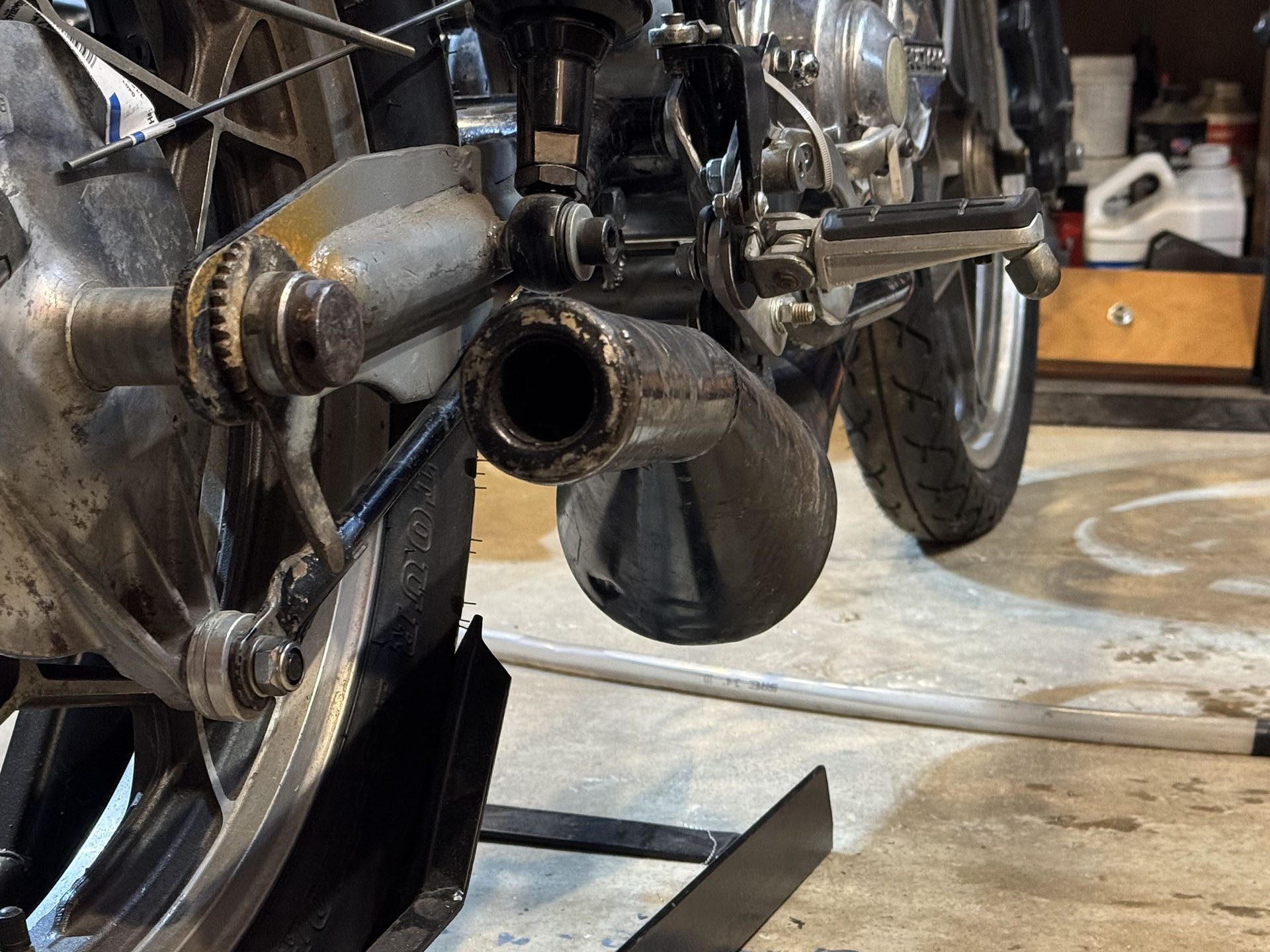

Okay, so not totally. I’ve collected more parts, scrubbed and sanded parts, and completed a few other minor bits of fabrication.

But as far as the swingarm mounting issue goes, I’ve decided to go back to the design I originally posted here on Nov 03 2011 — nine days after I started this thread. Every design I’ve come up since presents too many other functional or fabrication issues, or would require excessive cost.

After spending a year sketching, calculating, and pouring over fastener/bearing/bushing/tubing specs, I’ve concluded that going back to one of my earliest solutions is the only way to get off what has turned out to be an unending merry-go-round of “this-fixes-this-but-complicates-that” pretzel logic. I bought three different pivot bolts, frame tubing, and was about to sink money into high-end needle bearings and having a pro welder modify my swingarm to fit them. At that point I came to the conclusion that there isn’t an ideal solution.

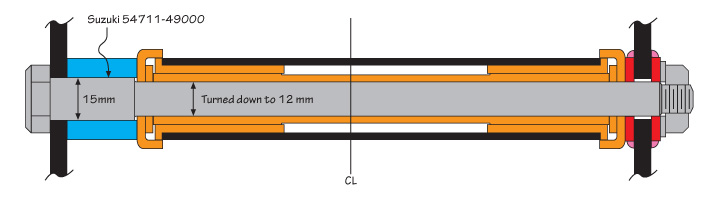

Remember this?

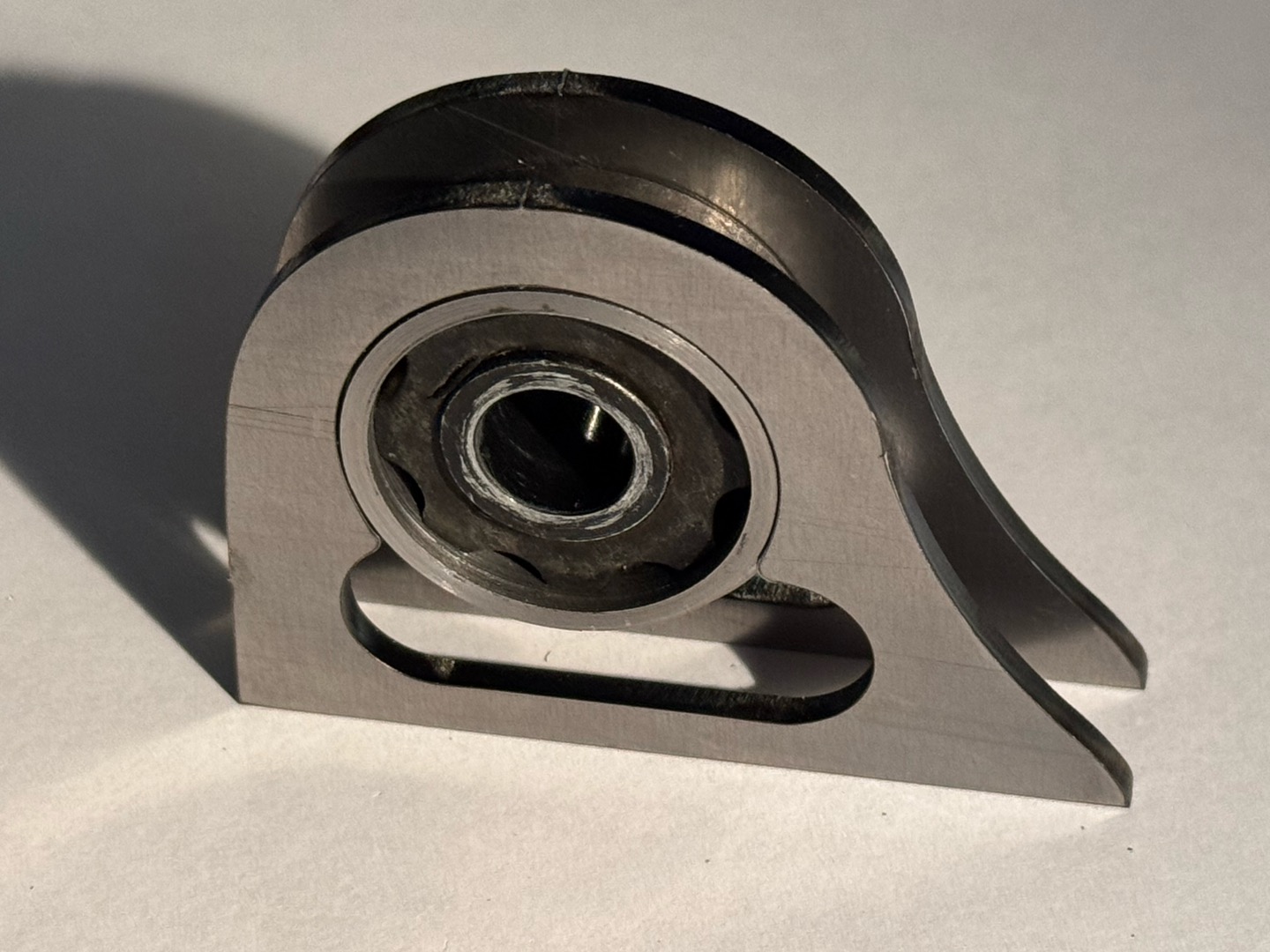

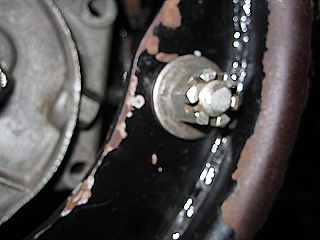

I’m back to working on this configuration, minus welding the second washer to the inside of the frame. (Turns out, there isn’t room.) SO, I reamed the right side pivot mounting hole from 14.3mm to 15mm, which allowed the hole to accept the 15mm Suzuki front axle I’m re-purposing as my pivot bolt.

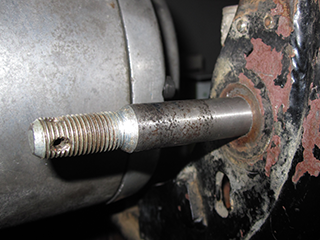

The axle necks down to 12mm threads, which can pass through the existing 14mm hole on the left side of the frame, but the shoulder behind the threads can’t. Fortunately, when pushed against the hole, the bolt shoulder’s taper forces the 12mm threaded portion to center itself within the hole. That allows me to locate a 1/4″-thick washer’s 12mm bore concentric to the original 14mm hole in the frame. I am doing this only to position the outside washer for welding; the shoulder will eventually be turned down and pass completely through the hole. Now I just need to sand everything down to bare metal in order to accurately weld the washer plate into position.

And while I’m doing that, my spare Suzuki axle is back in the hands of a lathe-owning co-worker.

With the exception of having the shaft turned down on a lathe, I’m back to do being able to do all the work myself. That’s what this whole project is about. Paying a welder to build a swingarm doesn’t teach me what I want to know.

I keep reminding myself not to think of this as my first custom build: it’s only an educational simulation, a dress rehearsal for maybe building a real custom bike someday. I am going through this process to learn what it takes.