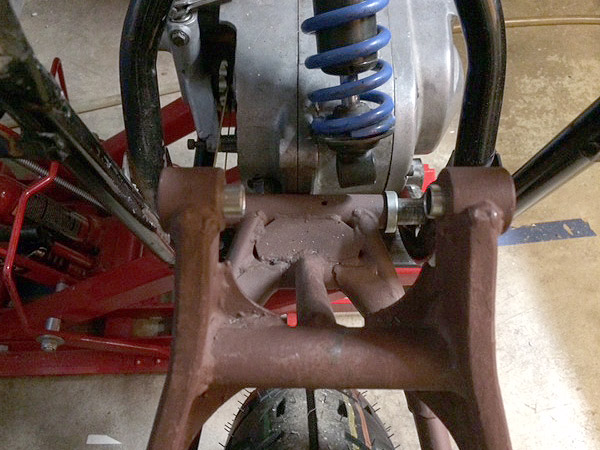

As I mentioned earlier, I needed to sleeve the shock mounting holes in the swingarm bosses down from 12mm to 10mm. Unfortunately, I couldn’t find the proper dimensions I needed locally, so I ordered these bushings from McMaster-Carr. Here they are pushed halfway into the holes. They’ll eventually be pressed in flush.

The cost? Only $2.83 each, but once you add shipping, it cost me almost $11 for these two little parts. Which brings up an important point with projects like this: one can quickly spend more on the little parts than the big ones. While that’s not exactly a stunning revelation, many people (myself included) can underestimate all the little costs of refurbishment that are easy to overlook when you’re appraising a potential project. The cost of bolts, bushings, gaskets and bearings really adds up. It’s easy to get caught in the trap of finding major, durable parts such as frame, crankcases and wheels that appear remarkably cheap, and immediately thinking you’ve scored a bargain. Compared with all the hardware needed to assemble the major parts you’ve found, and the wear items you really wouldn’t want to buy used, such as tires, inner tubes, brake pads, piston rings, cables, etc., the cost of the big stuff can actually be relatively insignificant.