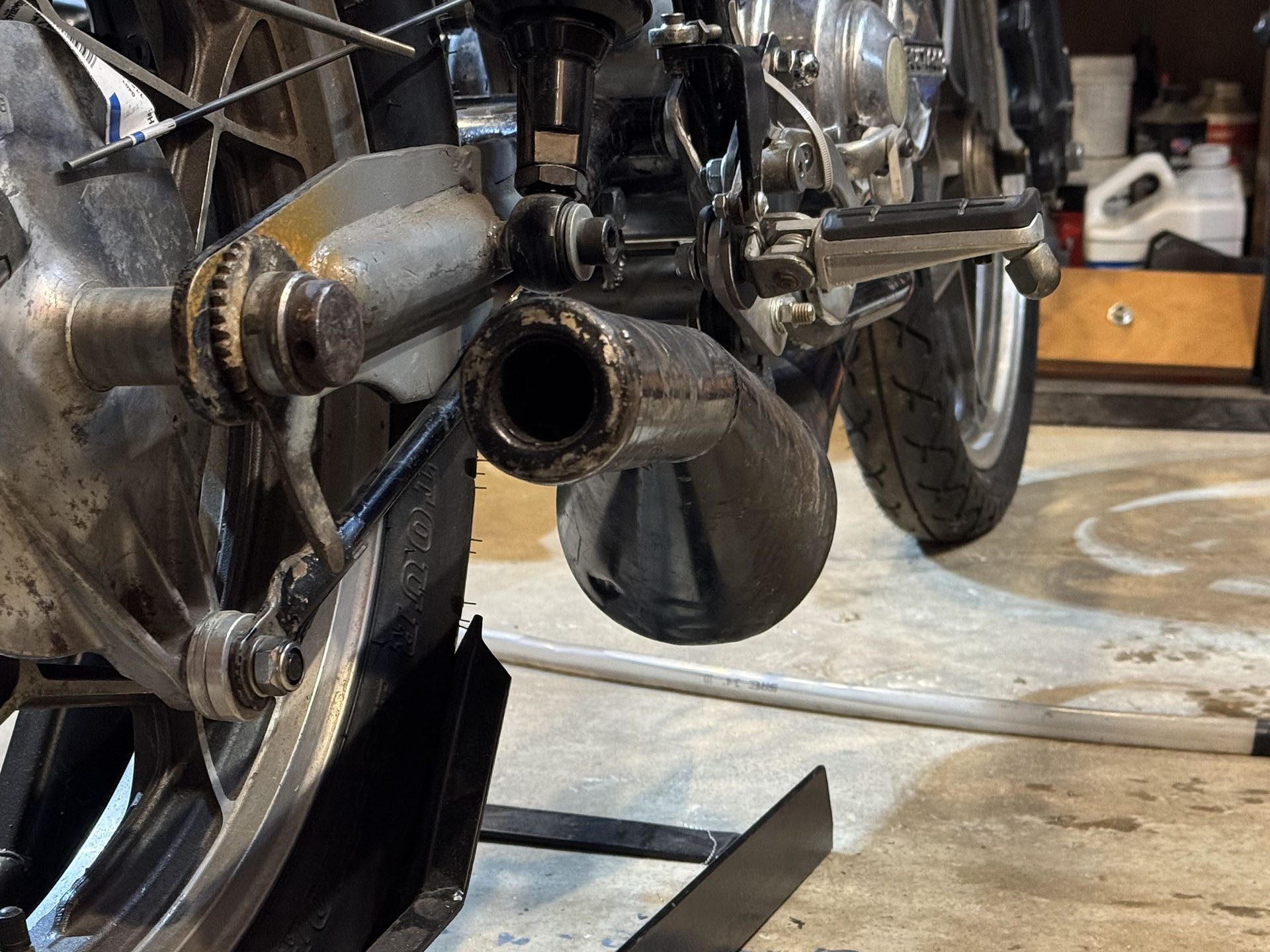

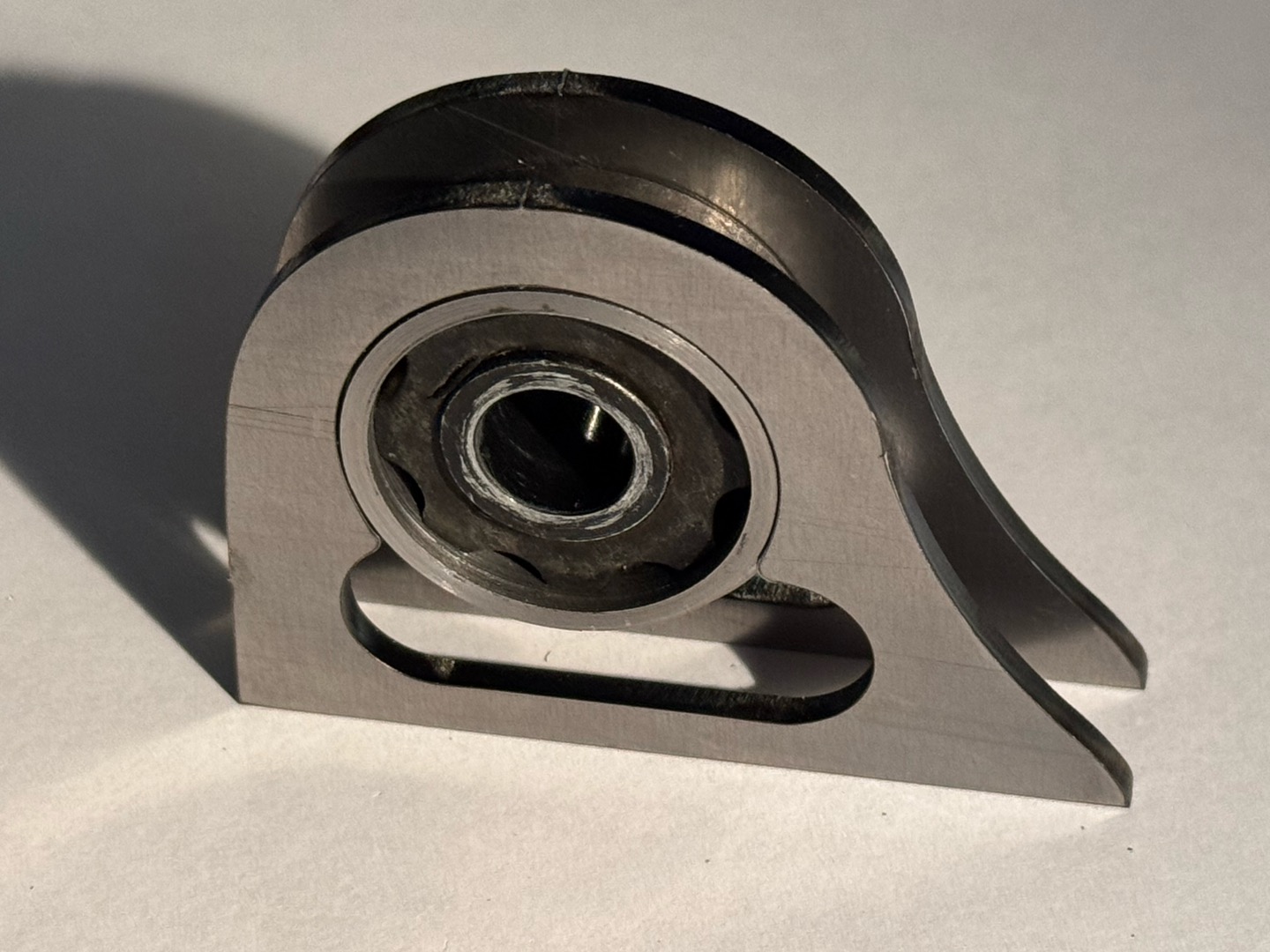

The rear of the crankcase will be rubber-mounted, but the front will be bolted directly to the frame downtube. An online acquaintance expressed concern that this arrangement might actually make vibration worse, not better.

Some time ago I had an OIF BSA A65 and my brother had a Triton with a unit 650 engine in a wideline featherbed frame. The guy that built it had used silentbloc bushes for the the front mount and alloy plates for the rear mount along with the usual head steady. I’m sorry to report that the vibration was terrible, bearing in mind that I was riding a far from smooth BSA at the time. To qualify that it did smooth out at higher revs, but for everyday use it was not very nice at all.

Having said all that, I wouldn’t change anything at the moment but be prepared for the worst.

He’s absolutely right; it might be horrible. It might have some weird harmonic and even break something. Vibration can be mysteriously complex behavior. I’m not an engineer and this is a more or less random collection of parts, so who knows? I have no idea what I’ll have, but as I have stated before, this project is all about going through the steps, and what I’m learning through the experience.

Fortunately, replacing the rubbers with a couple of alloy sleeves would be pretty easy to do. In fact, when [if] it’s running, I may do that as an experiment, just to see what difference it makes.