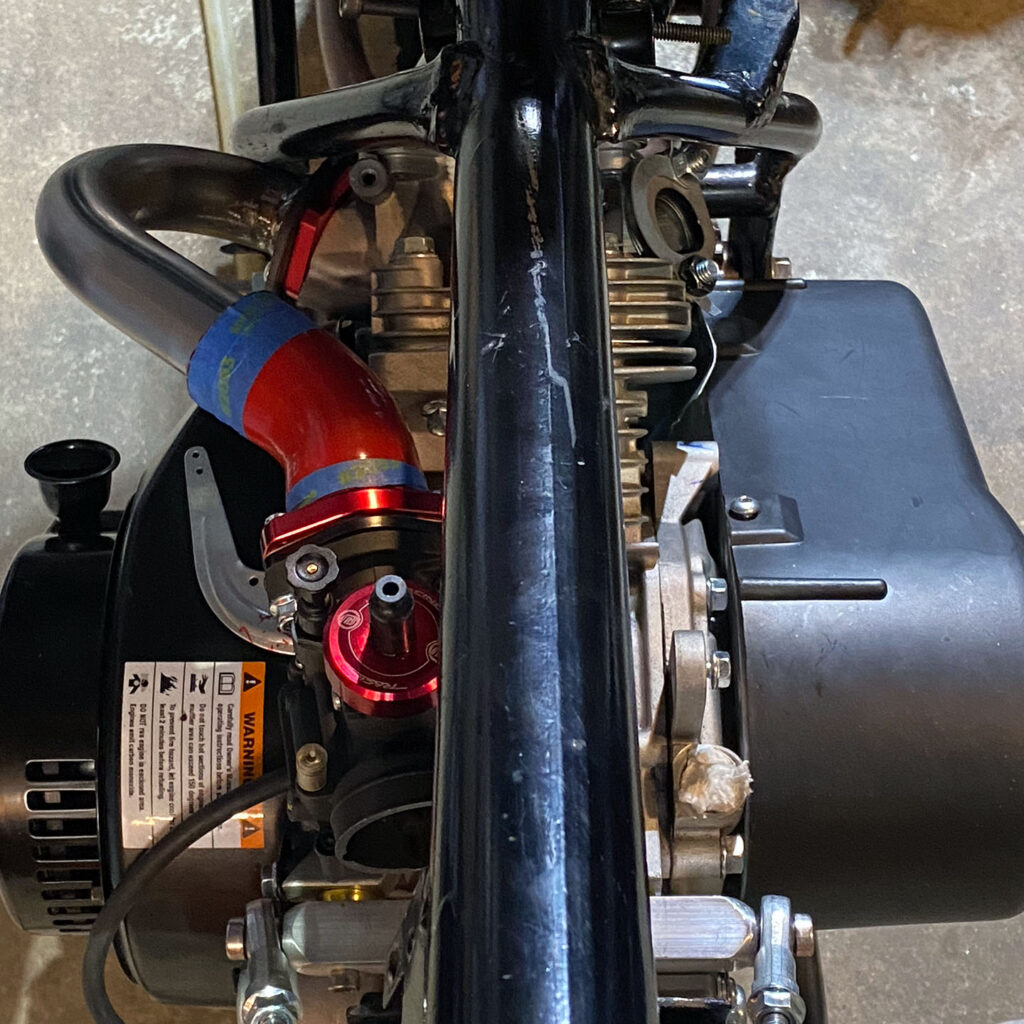

I’m working on the intake, and it’s taking more effort than I expected.

I did find a commercially-available plug-and-play option, but it puts the carb so far outboard that I would have to run the cable outside of the tank, and I want to route the throttle cable through the tank tunnel in the conventional manner.

I tried a straight u-bend, but putting the carb close to the center of the frame also put the float bowl pretty close to the cylinder fins — really not ideal.

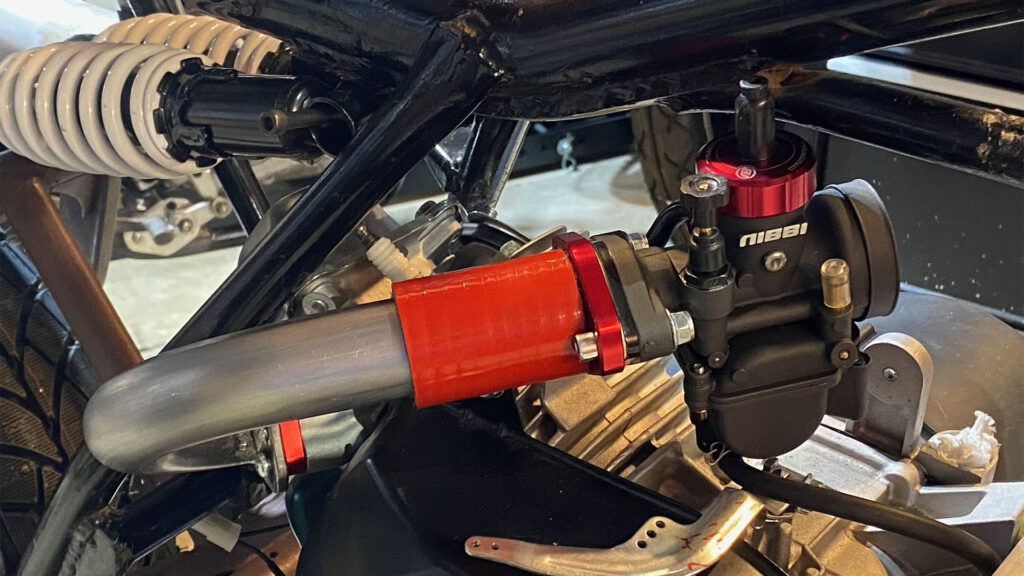

I slapped the 45° hose bend I had tried previously, and it moved the carb forward into a good position.

I verified that I will be able to get to the choke with the tank on.

So, there: desired configuration settled. But there’s still a long way to go. The hose section will need to be replaced by an additional metal section; that silicone hose isn’t fuel resistant, and even though it’s molded, it allows the carb to sag a bit.

But that’s okay; I need to start fabrication again from scratch anyway.

- First of all, I was overconfident about my welding skills. After taking a great deal of time to fabricate a flange and fit it to the U-bend, I totally gobbed the welding. (Totally — as in, I’m too embarrassed to show any close-ups. )

- Secondly, one of the mounting screws for the exhaust is right behind a frame tube. Removing the intake requires un-bolting the engine. It would be better to have the intake tract mounting bolts more accessible.