I successfully cut my battery box pattern out of 16 gauge steel I got from Lowe’s.

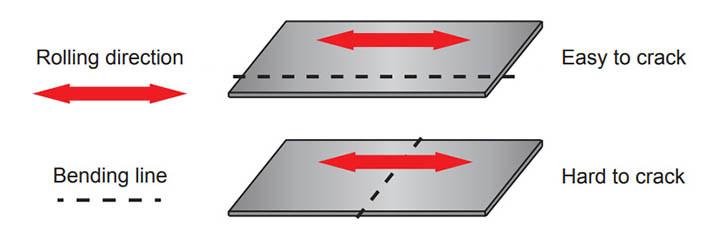

This is the point when things went amiss. You know that theory that rolled metal has a “grain,” based on the direction it was rolled? If not, here’s an illustration I found online:

Well, I thought it was just that — theoretical; certainly true, but the sort of thing that only aerospace engineers and production machinists needed to concern themselves with in practice. Well, I got a practical lesson when I attempted to bend my flat shape into a box, using my tiny Harbor Freight bending brake.

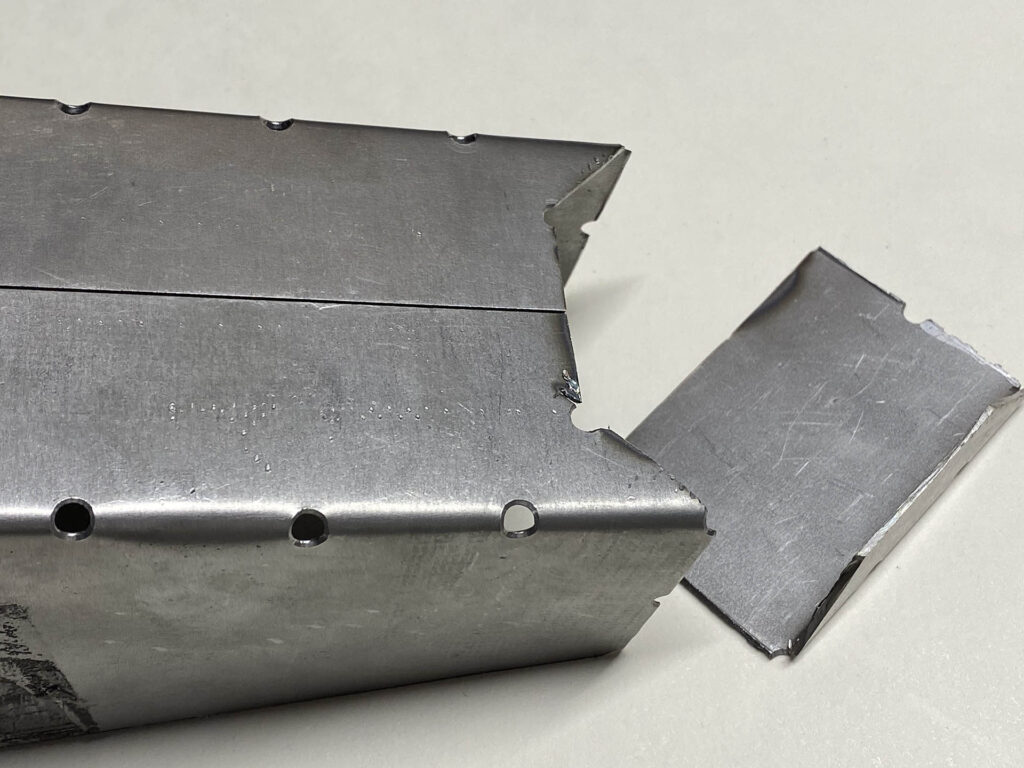

I bent the bottom floor pieces into place just fine, but when I moved to the vertical angles, three in a row cracked at about 50-60 degrees of bend. You can see from my bends in the other direction that I wasn’t trying to make super-tight-radius corners. (You can also see where I mis-drilled one of the perforation holes slightly. I have shamed myself.)

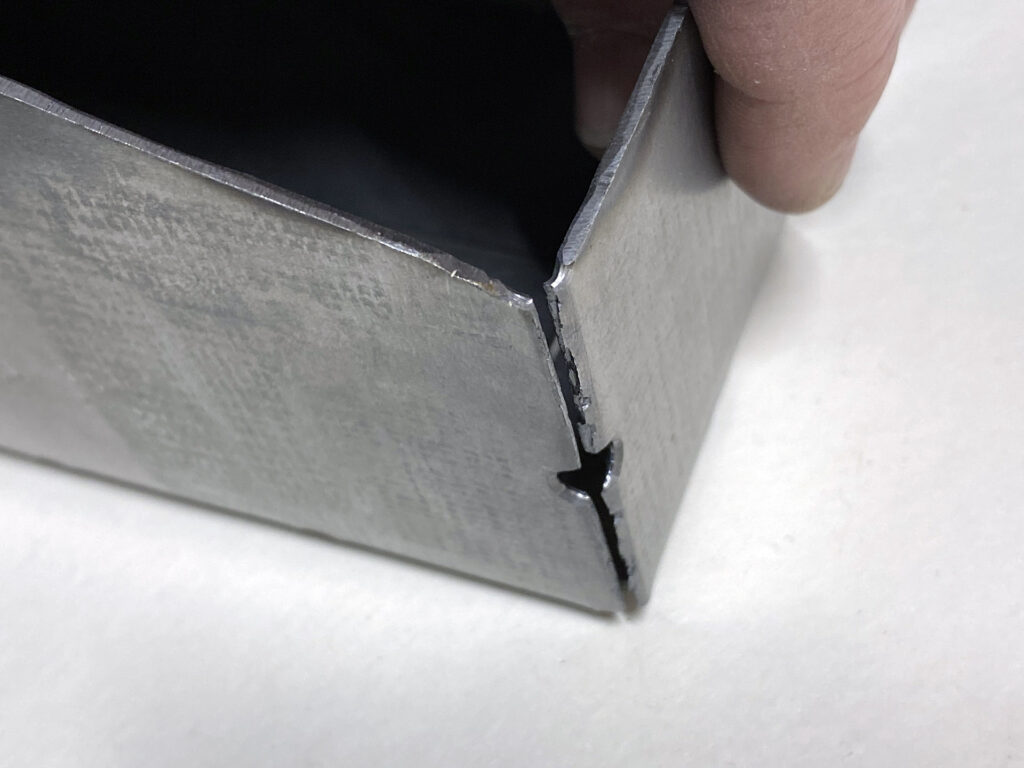

In the other direction, however, the vertical bends simply folded and cracked rather than smoothly bending. In this photo, I’ve already ground one side of the break smooth in preparation for welding, but it shows how sharply it folded before starting to crack.

A good dose of heat probably could have prevented this, but it didn’t occur to me because I’ve never had this issue before. In any case, a bit of crappy flux-core welding [that I am NOT going to show you] and I was back in business.

Unfortunately, all this is effort is most likely for naught. Looking where the finished box and battery could be located within the frame, I came to the realization that it just doesn’t fit. Not only is the battery way too close to the heat of the cylinder head, but the support brace on the Yamaha Monocross swingarm doesn’t have enough clearance. It’s tough to visualize based on this photo, but there’s only about 1-1/4″ between the bottom rear corner of the battery box and the vertical swingarm tube. I don’t want to hit a big bump and discover that the swingarm hits the battery box. I thought I could get away with it because the closest point of interference is pretty near the swingarm pivot, and the rear suspension only has about 4-1/2″ of travel at the rear wheel. Ultimately though, I had to admit it’s just too close to comfort.

Going forward, I have a couple of options. I could move the battery to another location. There’s an equally tight spot between the back of the engine and the swingarm pivot, but proximity to the cylinder cooling fins would still be a concern. Alternatively, I do have another, physically smaller AGM battery on hand. It would be much easier to mount, but it’s an off-brand, 3 AH battery intended for my kickstart-only Bultaco 360 roadster. It’s rated at only 50 CCA, too small to reliably spin The Bride’s electric starter. I chose the existing battery — a Motobatt MB5.5U rated at 90 CCA — because it was as small as I dared go.

So, I now need to do what I always do at these junctures: go down to the workshop, pull up a stool, stare at the bike for a while, and think.