You know that whole part about swapping the engine in without cutting the frame?

No matter how I reoriented the engine and torque converter, something ended up bumping into the frame somewhere: the flywheel, the cylinder head, the starter motor. At one point, I was willing to lose the electric start if that would have allow things to go into the frame, but ultimately that wasn’t a magic bullet.

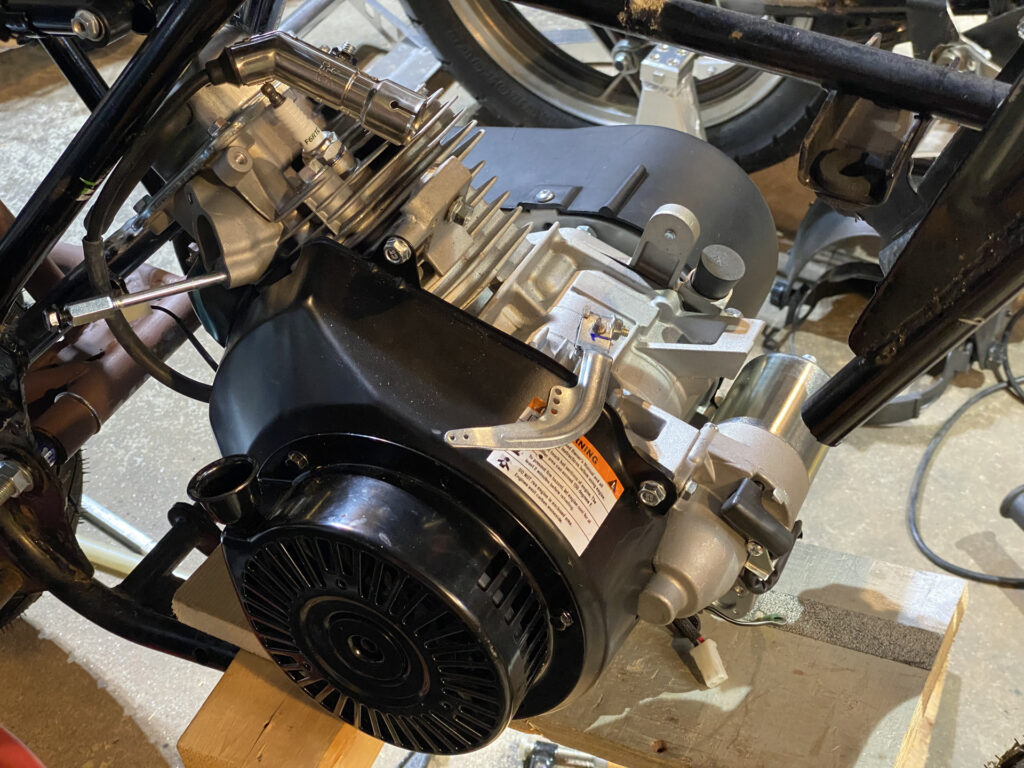

So, after a bit of measuring and a long time staring at the frame and trying to think things through, I bit the bullet and whacked the down tubes off. With that done, I could prop the engine up on wooden blocks to figure out where it had to go, in order to figure out where the frame could go.

This view gives you an idea of the tubes’ original path. Even without the starter, the flywheel and torque converter would have been in the way.

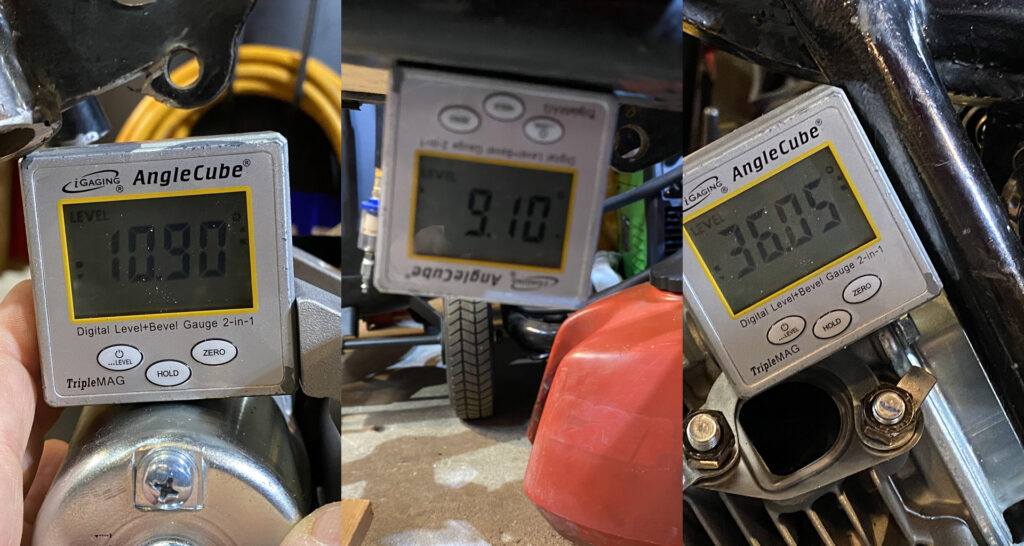

It took a lot of jockeying around, but once the engine was sitting properly, I got out the angle cube and did some measuring.

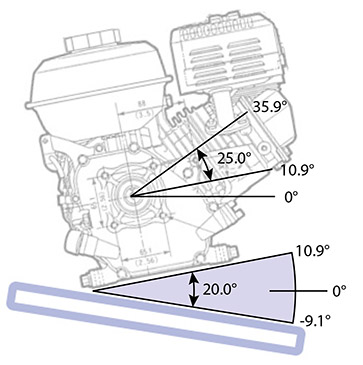

The engine was inclined at 10.9° forward, nicely within the normally accepted 0° – 15° “safe” range for a GX clone/Pedator engine. As the bike sits, the lower frame tubes of the SST frame are –9.1° from level. The forward seat tube is 36.05°, and the top of the cylinder head is “eyeball close” to parallel. I know the GX/clone engines have the cylinder inclined 25° from horizontal, so my numbers all check out:

So, my next step is to make an engine mount with an included angle of 20°, and get everything bolted up with the torque converter sprocket properly aligned.

After that, I will have to figure out how to configure replacement frame tubes. For this, I’ll be using the Ridgid #368 bender (3/4″ OD x 3.75″ radius) that I bought to modify Bultakenstein’s frame. I got a cheap score on a few 3-foot remnants of 0.75 OD, .065 wall, unspecified “carbon steel” tubing. The existing frame tubes are 7/8″ OD x 0.95″ wall, so these are thinner and the smaller OD will be a visible mis-match, but so be it. For what a different mandrel bender would cost, I am super okay sticking with the OD that matches my tool. Even the tools for this project are whatever I have lying around. And even though my bender is rated for up to .120 wall, the 0.65 will be just fine for this application (and as a bonus, easy to bend).