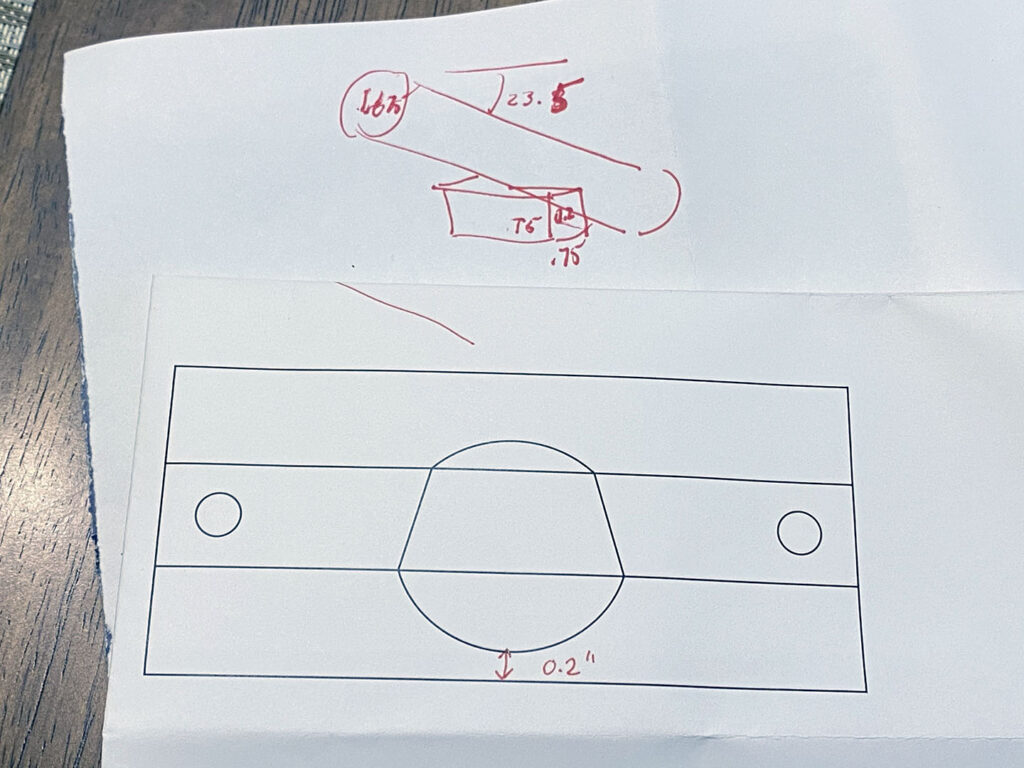

My first freehand attempt to create a cutout in the center of the tank mount for the Bride’s main frame tube was fairly sad. Afterwards, I devised several ways of mapping a more accurate template, but then I decided to flex my math skills and actually calculate the shape of the opening. A few quick measurements gave me the vital specs: the OD of the frame tube, the outside dimensions of the crossbar, the angle of the frame tube, and the point at where they intersect. A couple of back-of-the-envelope calculations gave me the specs needed to draw the shape in Adobe Illustrator.

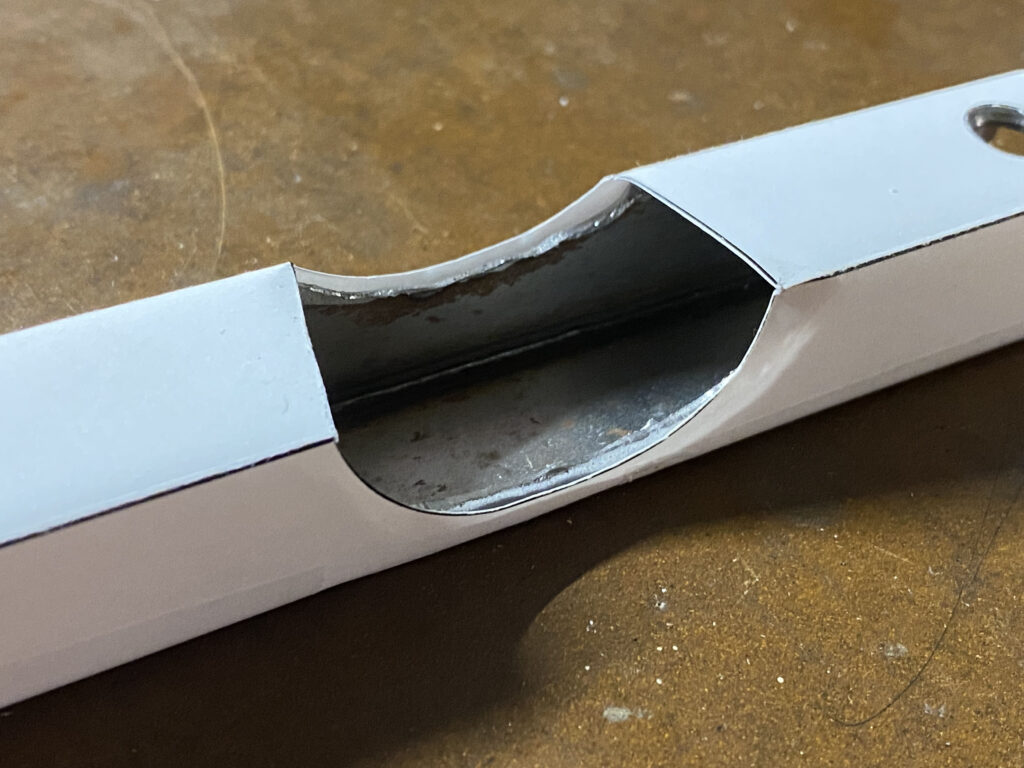

With the diagram printed off full scale, I could cut the paper and wrap it around the square tube. You can see how far off I was when I tried to do it by eye.

Slipped into position, the shape looked pretty much spot-on, front and back.

I’ve ordered a 1-5/8″ bi-metal hole saw with a -0.64mm smaller radius than the frame tube. That should be just about perfect.