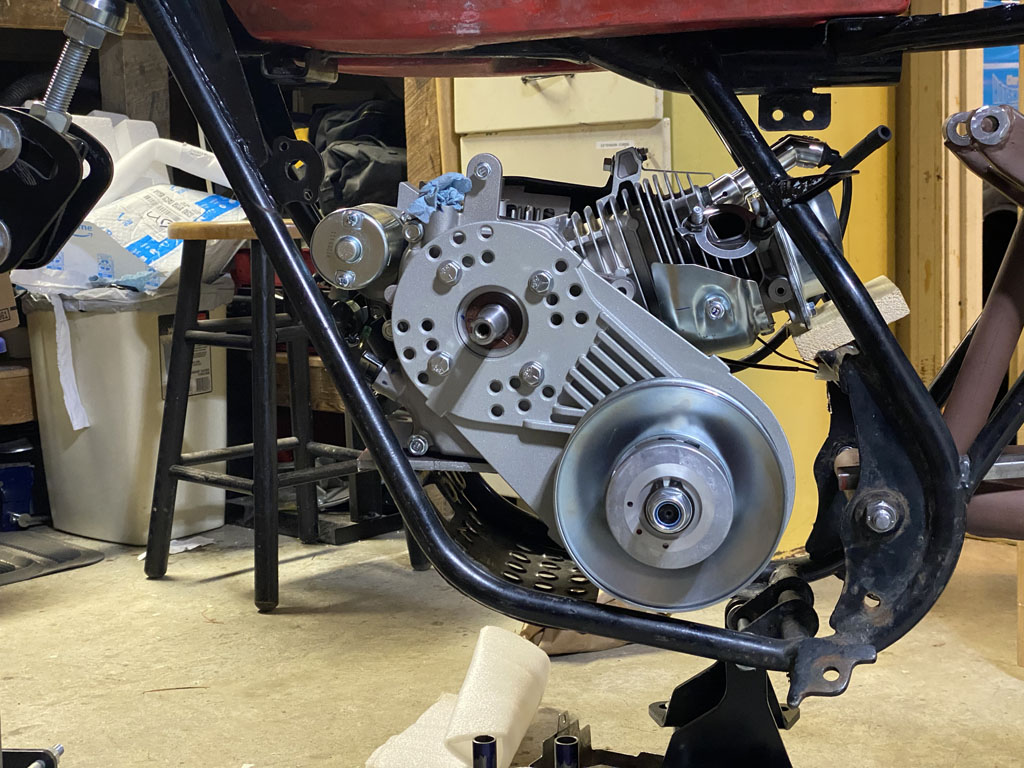

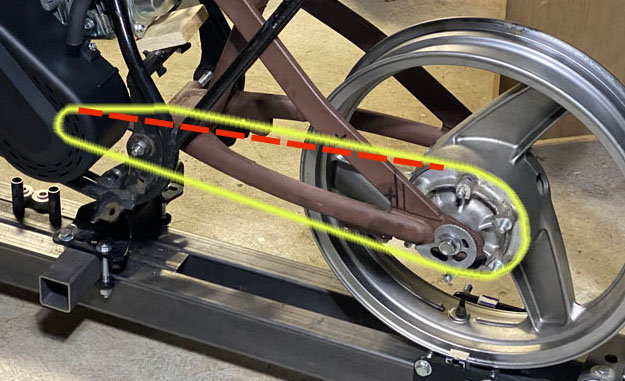

If you look at my earlier mockup of the frame and swingarm, you can see that that the output sprocket is rather far from the swingarm pivot. Furthermore, the swingarm is at a pretty significant downward angle.

This is likely to cause issues with chain clearance and tension. The chain will want to run straight through the swingarm pivot, especially as the suspension moves.

I don’t know if it’s necessary, but one idea to resolve this would be to run a narrow jackshaft with twin sprockets directly on swingarm pivot bolt. With such an arrangement, the chain geometry would remain consistent as the rear suspension moves.

To make this happen, I would have to cut some width off the left side of the swingarm’s pivot and shift the left swingarm bushing closer to the centerline, making room for the jackshaft between the left side of the swingarm and the frame.

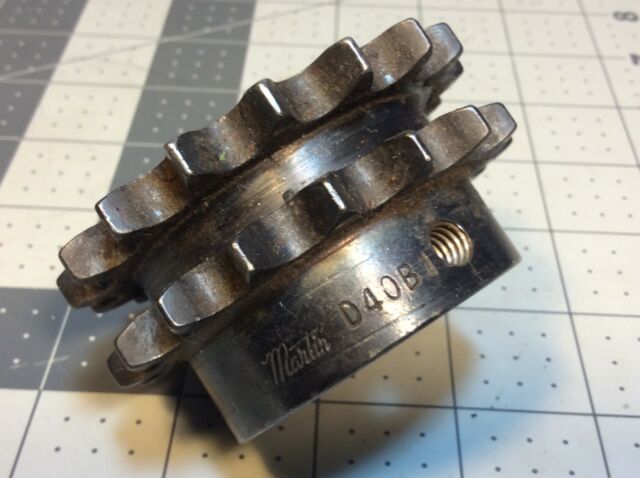

This old duplex sprocket doesn’t have enough clearance between the two sprockets to run two separate chains, but it illustrates the idea I have in mind. Instead of putting it on a shaft, press in a couple of sealed ball bearings with the proper ID, and slip it on.

This arrangement would have the fringe benefit of allowing me some flexibility in the positioning the engine/CVT side-to-side in relation to the chain run to the rear wheel.