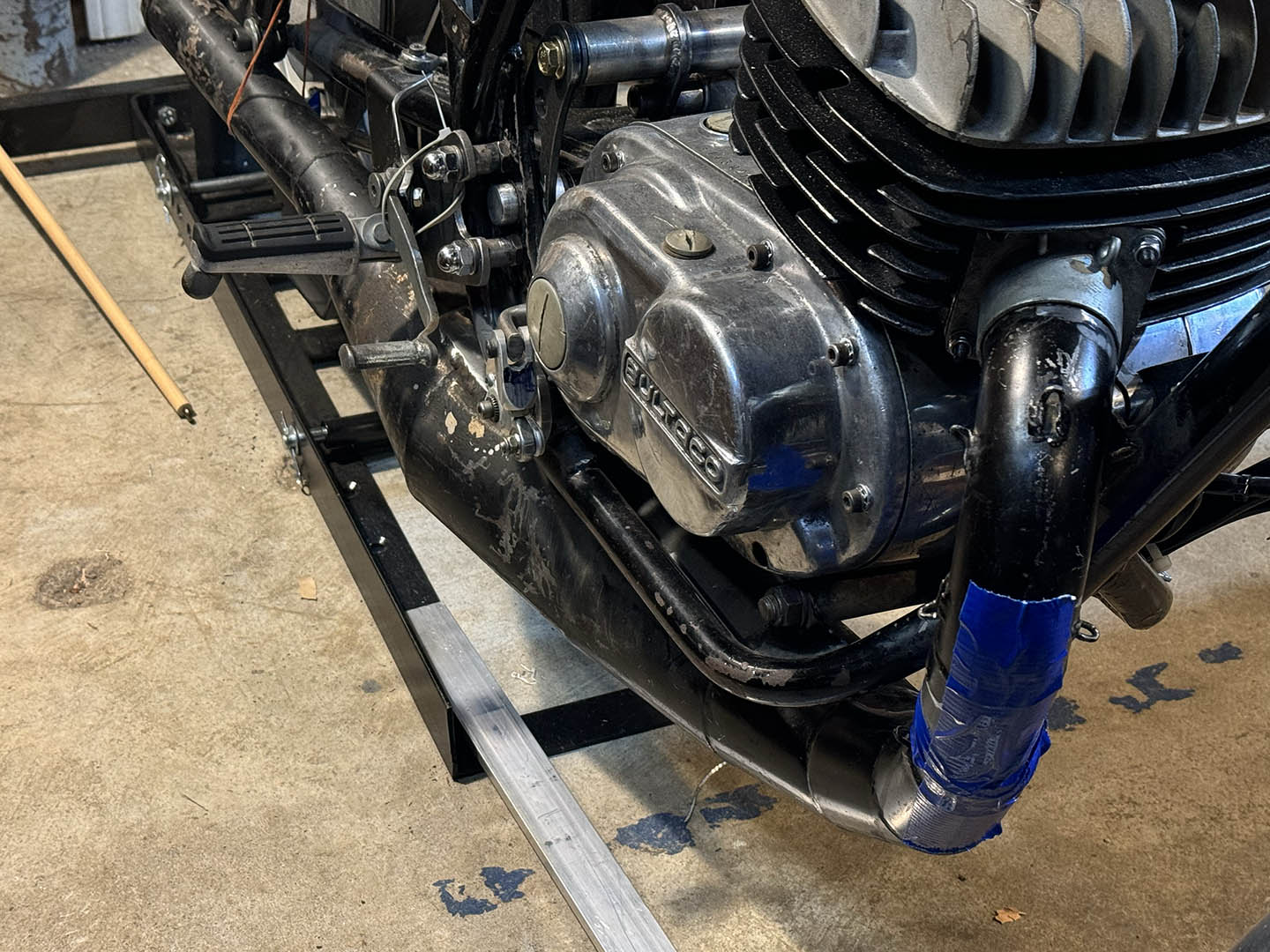

With the swingarm clamped in place, I briefly played around with the rear axle.

All sorts of finagling will be needed to align the rear rim and rear sprocket, both of which are wildly off in stock GS450T configuration, but we’re not ready to go there quite yet. I’m taking one baby step at a time.

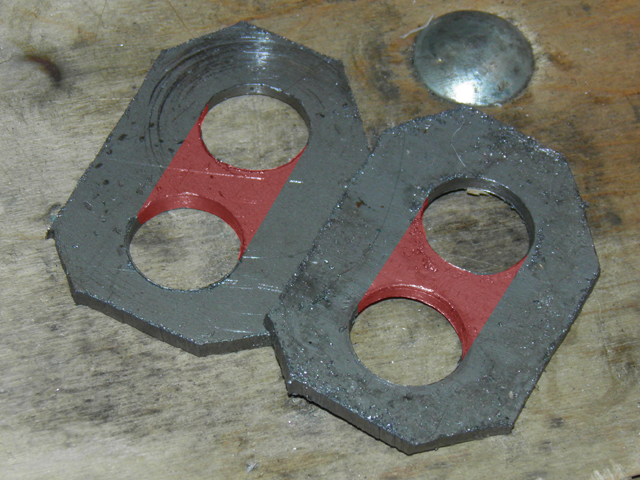

Since the side plates on the Yamaha swingarm are thinner than those on a GS450, I have to make plates to widen the swingarm to match the Suzuki adjusters. These will be welded onto the outside of the swingarm axle slots. The photo above shows them mid-fab. At this point, I still needed to remove the red shaded areas and round the jagged outside edges into smooth curves.

The finished shaping the rear axle reinforcement plates are certainly not show quality, but they look a lot okay, and more importantly, they’ll be functional enough to solve the issue at hand. Sure, they’re basically two over-glorified washers, but with just a hack saw, a flat file, a round file and a dremel tool, I’m happy to have created any sort of part at all.

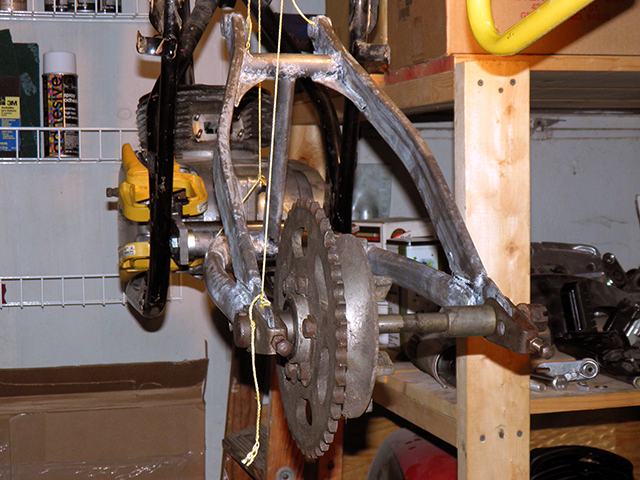

And here’s where they’ll be welded onto the swingarm. I’ve got some welding training and a Clarke spoolgun MIG, but I’ve been hesitant to do my own welding on a motorcycle. This is a good prospect to test my skills, because in use the plate is clamped in place, and even if loose would remain fully captured by the axle. I am not sure if I’ll just drill a couple spots in the plate and tack weld, or run a bead around the perimeter. The welds’ only purpose will be really just to keep the place aligned around the slot and in place when the axle is loosened or removed. Also, on some production bikes, these plates are screwed on with flush countersunk cheese head screws, so, the precedent is there to just screw them in place, as well.