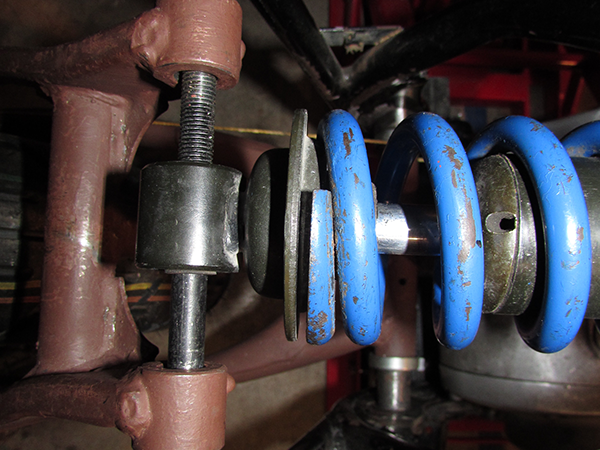

Well, I swapped the XR80R spring onto the Blast damper body. It worked…barely. the Honda spring was just slighty smaller diameter, but there IS a hairsbreadth of light visible between the coils and the shock body. The Blast damper has a surprising amount of gas pressure without a spring installed. The XR80R shock has zero pressure, literally; without the spring, you can move the piston through its travel and it just stays put where you left it. The XR80R/Buell combination is, therefore, still significantly stiffer than the Honda shock, with no measurable static sag. But I can get it to compress by adding my body weight to the back of the bike.

Since diameter of the Honda spring is just slightly less, it only seats about halfway down in the retaining collar. Somebody tell me if there is something catastrophically dangerous about not having the spring flush against the bottom lip of the collar. The collar and spring are square on the shock, however.

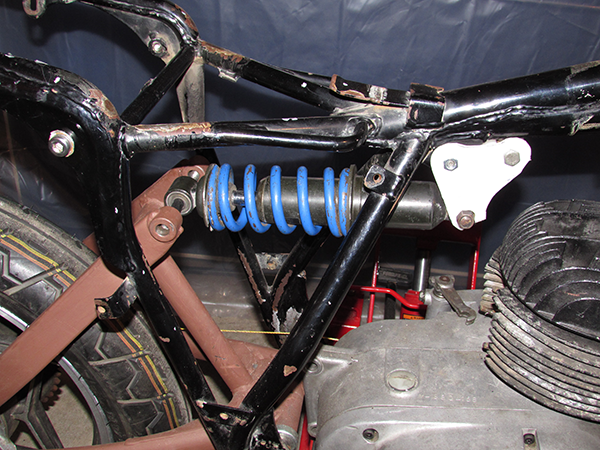

Ideal? Not by a long shot. Both the physical configuration and the function are not what I’d like. But workable enough for me now? Yes. I wouldn’t want to ride it very far like this, but it is good enough to continue my build around it. There are a million other things I’m anxious to address on this, and there are plenty of ways to improve the shock later. If I ever get this thing finished and running, and it turns out not be a total piece of excrement after my first test ride, I might be willing to give Works Performance or Elka a call and spend the big bucks get a decent custom replacement. Here’s shot of the franken-bike with the franken-shock installed. For now, I’m calling it good.