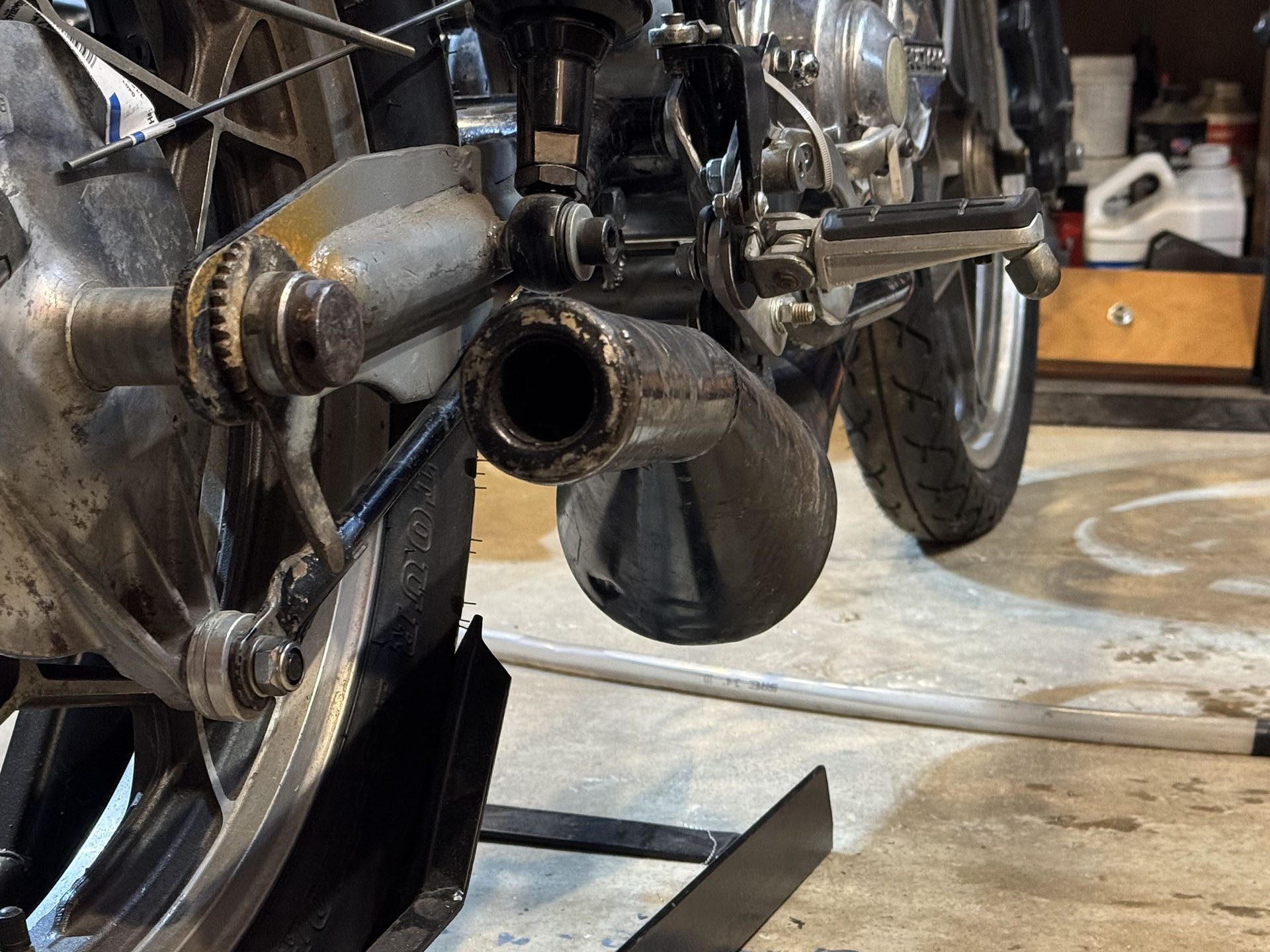

The bearings and seals for the rear wheel were delayed a week, evidently because of winter storms. I just got them Friday afternoon, and have not had a chance to put my wheel together. I hope to do that in the morning.

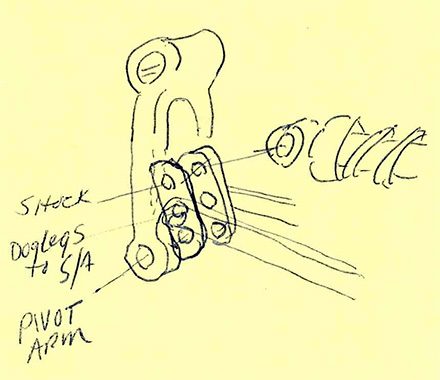

While I was waiting, I delved once again into the quandary that is my rear suspension. I spent a lot of time online and in books getting a better idea of exactly how rising-rate linkages work, and I drew this quick post-it note sketch of what I thought might work in my case:

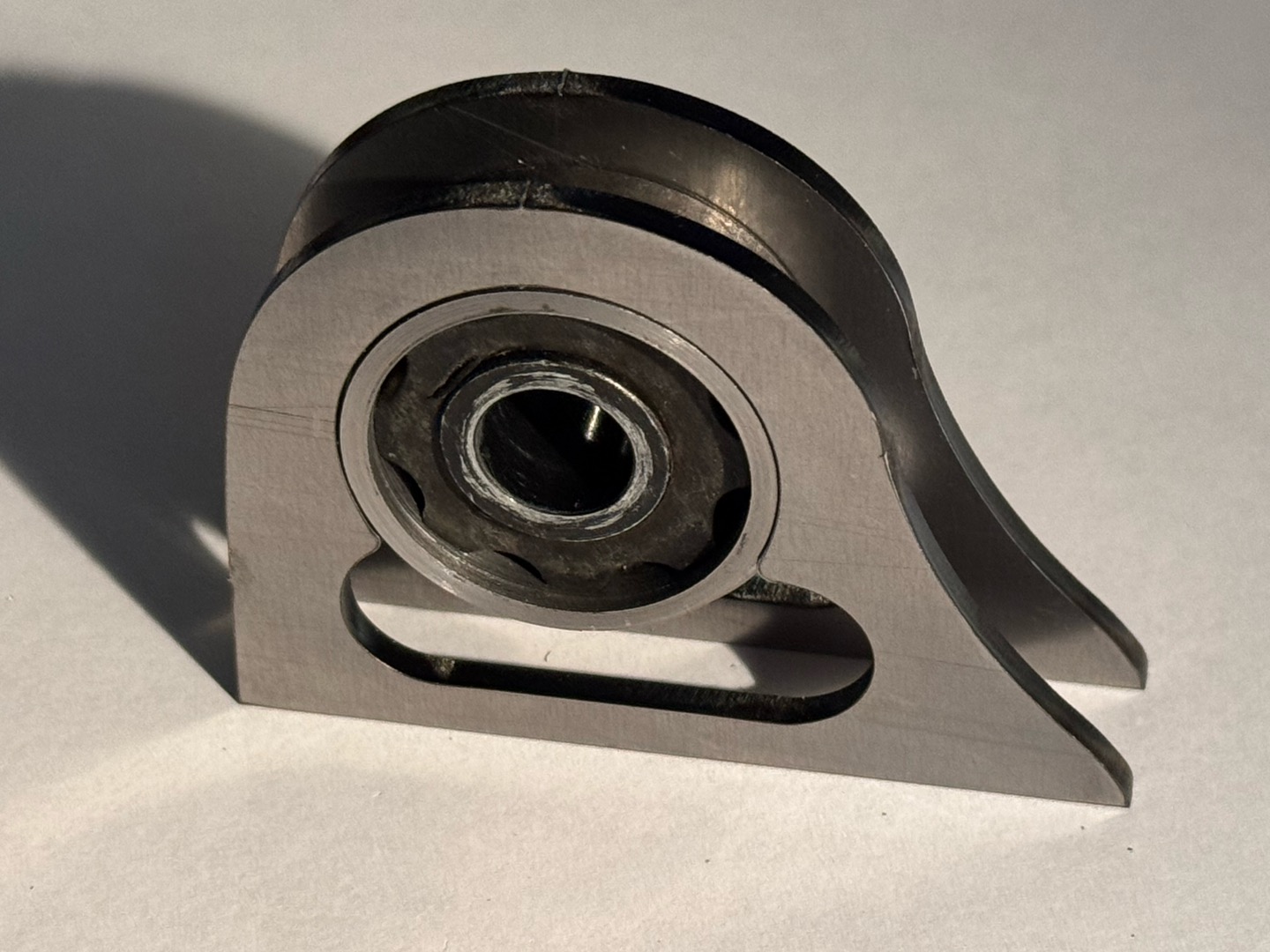

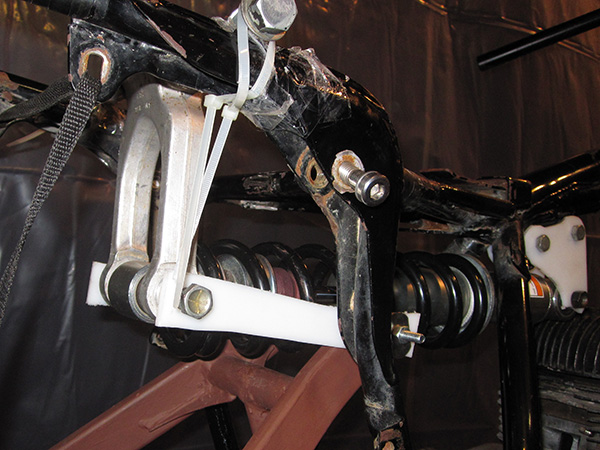

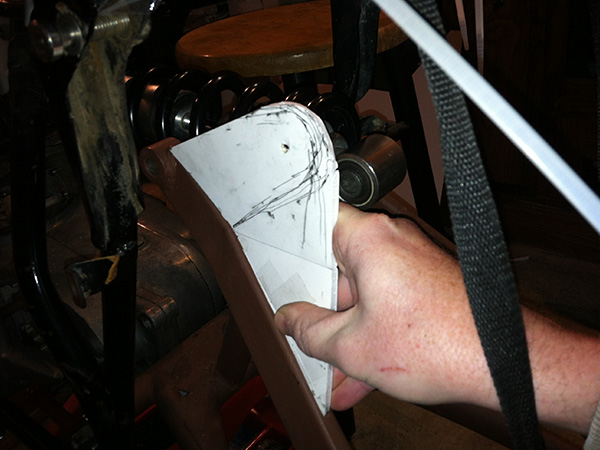

Here I’ve mocked it up, but for simplicity I’ve mounted the doglegs, shock and U-linkage all through the same bolt. Obviously, I would want to stagger them for the rising rate effect shown in my crappy drawing.

Everything could fit together this way. But of course, there are always plenty of compromises and limitations. First of all, wow, this is getting complicated. Secondly, the space available for my damper unit to move around in is pretty limited, which would pretty much dictate my suspension rate geometry for me…and I doubt it would be optimal. Thirdly, that’s a whole lot of crap up high in the frame and far away from center of mass. And finally, here’s the kicker: look where that bolt I’m suspending the U-linkage from is located. Yeah, that’s zip-tied to the seat rail—not a very practical mounting point, and that’s a part of the frame that really wasn’t designed to take a lot of stress. The U-link is really only there to handle the side loads from the shock, but since I have absolutely no way to calculate what sort of loads would be transmitted to that upper pivot, I need a better, more robust, more secure method of locating that link. So, I devised an even more complex, heavier, harder to construct sheet metal box that would weld in between the seat rails and tie the linkage to the front of the shock together directly, isolating a lot of the suspension stress from the frame.

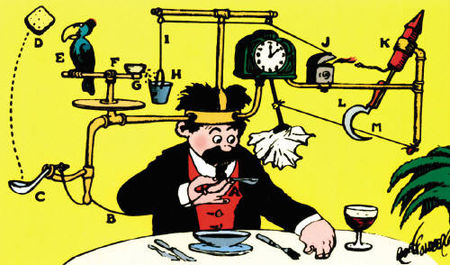

With every new solution, things are feeling more and more Rube Goldberg-ish!

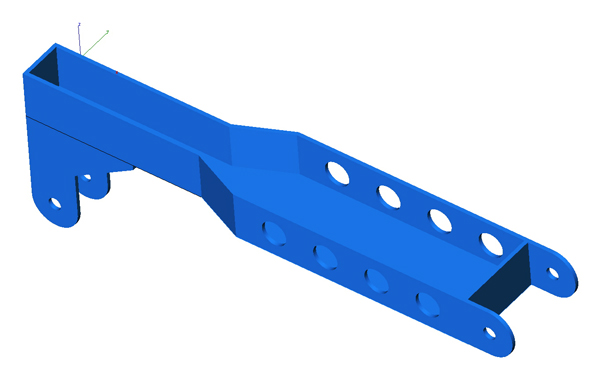

So I thought, there’s got to be an easier way. I wondered if it was possible to turn the U-link over and mount it to the swingarm, below the shock. Of course not. But that thought process made a light come on: as long as I am considering welding some mounts to the swingarm, I could make this much easier and straightforward:

Do away with the linkages all together and simply weld mounting plates to the swingarm that will carry the rear shock eye!

I had considered this very early on and it didn’t seem like the most appealing option back then. Now it does. It’s no less functional than the whole plumber’s nightmare I was considering with the linkage, and the Yamaha Raptor ATV my shock comes from does not use a linkage design. My “rising rate” geometry was going to be pretty conservative anyway, and possibly nowhere near optimal, so I don’t think I’ll be too bad off going with the shock solidly mounted to the swingarm.

I may go back and play with my linkage idea a bit more before I commit, but right now I am leaning heavily toward the more streamlined solution.