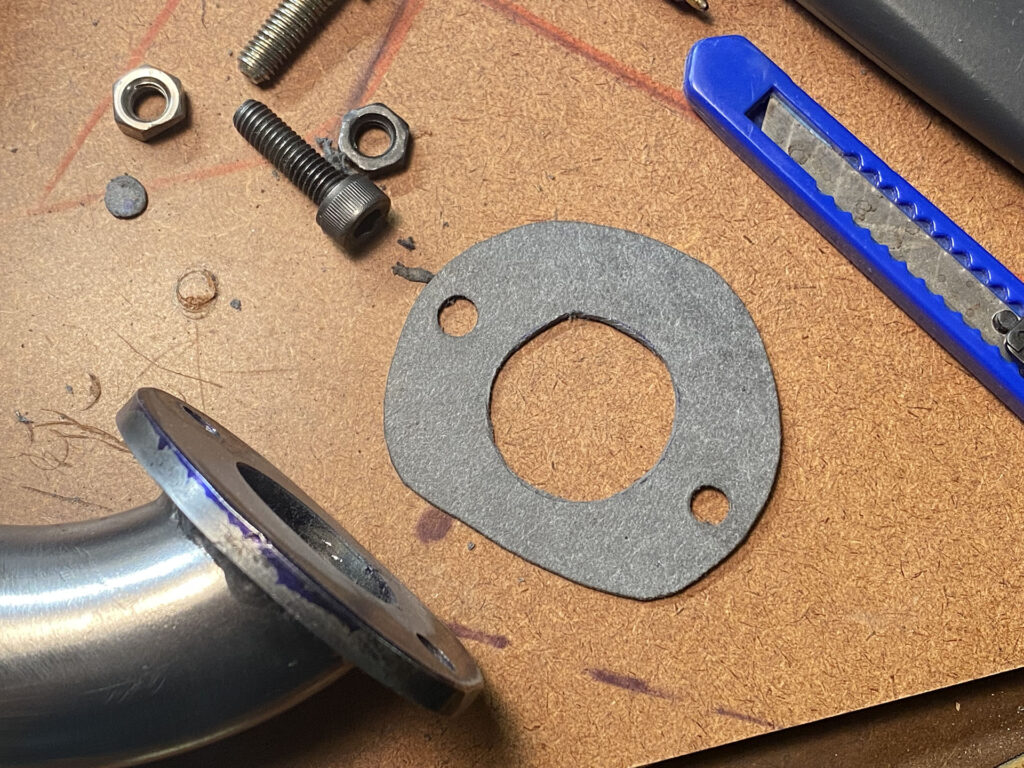

My suspicion that my intake tract wasn’t airtight proved to be correct, and the reason was quickly and painfully obvious. I had totally skipped the build step of creating a gasket to fit in between my head adapter and intake pipe. I had assembled it with nothing between the two metal surfaces. To make matters worse, the two countersunk bolts, by necessity, sit slightly below the mating surface. You can see here that there is very little material surrounding them, so there is plenty of opportunity for air to sneak past in the best circumstances.

I cut the gasket I needed from a sheet of high-quality gasket material (Fel-Pro 3157 — 1/32″ rubber-fiber, fuel/oil safe). I can seal things up further by adding a flush skim of RTV silicone over the screw heads with the adapter installed and torqued down, if that turns out to be necessary.

I checked all the mating faces by coating them with layout blue and then and then lightly rubbing them on a plate covered with 220 grit emery paper. In the above photos you can see that the adapter flange was spot-on flat. The two end plates of my intake tube were not quite as true (after all, they had been welded), but likely good enough for a bit of gasket material and properly torqued bolts to keep things acceptably sealed.

I bolted everything up, and it did, indeed, start and idle much better. It still needed choke and wasn’t perfectly smooth, but much, much better.

I must sheeplishly admit to why my kill switch leads weren’t functional. I had plugged them into the wrong connector. The wires at the rear of the engine are the kill mechanism. I think the identical connector at the front is an oil level sensor, perhaps? In any case, touching them together kills the engine now.

Unfortunately, there’s enough play in the mounting holes that the carb was positioned just a skosh higher after re-installation, and the choke plunger touched the bottom of the tank. The choke kept spontaneously snapping shut — er, open. I loosened up the carb bolts, shifted its position slightly, and tightened them back up. I started the engine and let it idle a bit longer. This time the choke stayed on. When I went to shut it off, I saw a small piece of black plastic lying on top of the engine. Oops, I guess I was a bit too vigorous in re-tightening the carb bolts.

The carb is so far away from the engine block that it really doesn’t need an insulator, so I might re-make this out of alloy. Somewhere in that process, I might be able to create more space between the tank and the choke knob in the “up” position. I will also make some sort of brace or bracket for the intake pipe, so it doesn’t vibrate itself to pieces. So, there’s still plenty of work to do.

I will need to develop some carb tuning skills. The jetting is clearly way off; the engine won’t rev smoothly and won’t idle without choke. I have very little experience with the sort of methodical diagnosis required to get a bike fueling well across all throttle positions and engine speeds, so it’s another opportunity to learn. Or perhaps to make negligible progress for an extended period of time. We’ll see.