The extremely long intake runner needed some sort of support, so that the welds at the head flange were not supporting the entire weight of the carb and air cleaner at the other end. In addition, letting it hang off the engine creates a very large lever, amplifying vibrations the carb would experience. And GX clone engines are very buzzy.

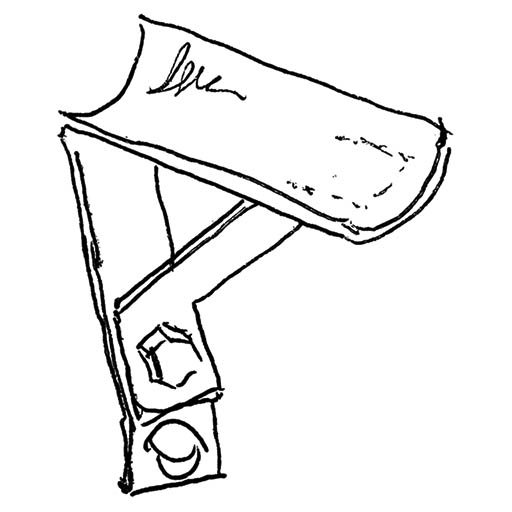

So I came up with the idea for a support bracket that would mount to the top of the engine and clamp around the intake pipe. There are two unused bosses in the crankcase — an M8 and an M6 on different planes. I can only bend up to 18 ga steel in my tiny brake; I figured that was a bit skimpy to do a single bent bracket. I’d need to triangulate the bracket for strength. My concept looked like this:

When I got all done fitting, bending, cutting, banging, filing, gouging, welding and grinding, this is how the real version looked:

Wow, that’s ugly. But despite being crude, convoluted, and amateurish, it fits perfectly and its strength is more than adequate.

You’ll notice how scratched up the satin black is on the intake pipe in this picture. “Paint-and-primer-in-one” my ass, Krylon. I stripped and repainted it. “Stripped” is probably overstating it; the paint literally wiped off with an acetone-soaked rag, despite being painted weeks ago. I re-did it with Eastwood’s Brake Gray, which is an admirably tough and attractive finish.