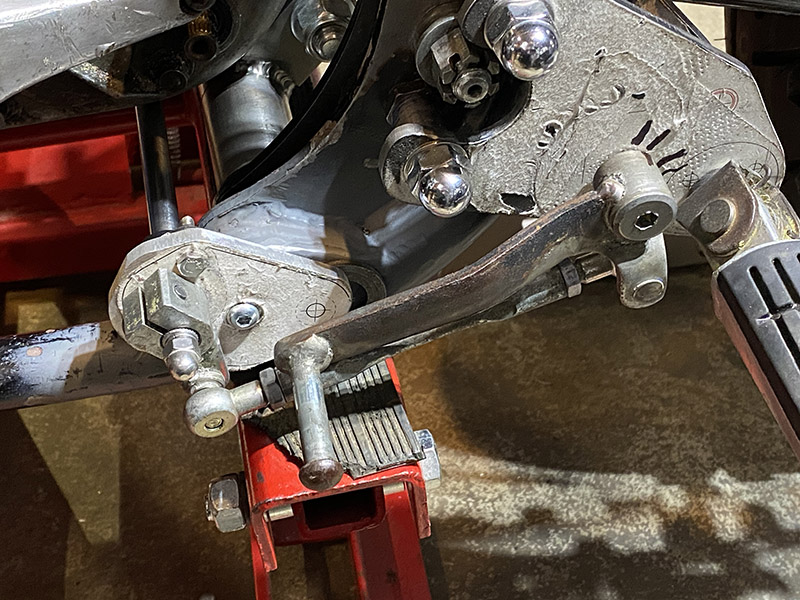

Playing around with the shift linkage some more, I’ve decided to go back to how I had configured it originally—with the bearing mounted to the inside surface of the plate and the clamp oriented with the spherical joint facing outward. This makes the whole thing narrower overall, and looks just a tiny bit less bodgy. (Or at least it will, once I strip the oil-soaked paper templates off the mounting plates.)

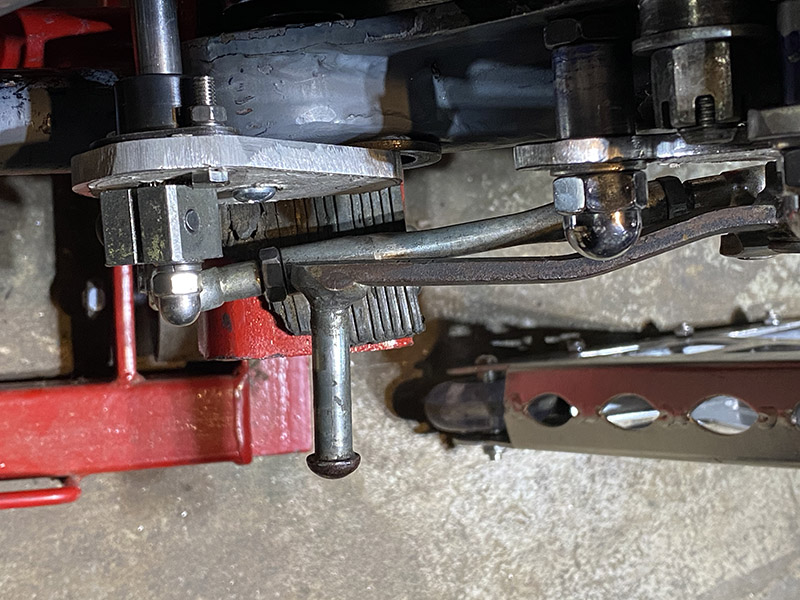

The issue with this configuration is that the linkage arm fouls the pedal travel. I am just going to bend it to put more kink in the pedal arm and shift the toe end outward a bit. It won’t take much to clear it. As it is, the pedal just barely clears the acorn nut for the footpeg mount, so that will be a good idea for two reasons.

If you look close, you can see a thick washer wedged behind the rear of the bearing mounting plate. It’s there to compensate for for some Catalan craftsman’s somewhat lax standards of precision back in 1977.

TRIVIA TIME

Did you know that Bultaco never manufactured frames in-house?

They were built to the factory’s specs under contract by Monfort, a small firm NW of Barcelona, about 20 miles from the Bultaco factory. In 1958, as F. X. Bulto was starting his own motorcycle business, Monfort was struggling to sell a line of rather crude, less-than-reliable motorbikes. Bultaco bought Monfort’s license to manufacture motorcycles—required in Spain at the time, but severely limited by Franco’s autarkic bureaucracy. In exchange, Bulto promised to ensure Monfort’s survival as a frame builder for the new firm.

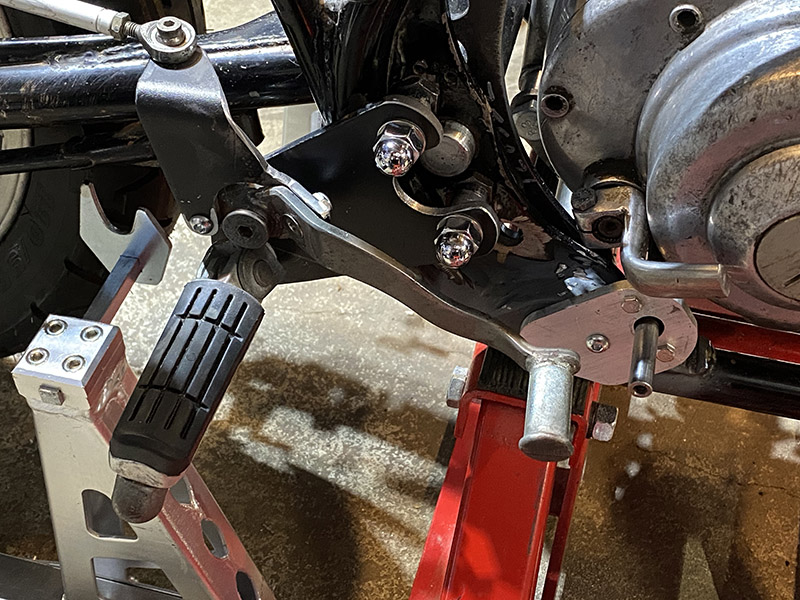

Moving over to the right side of the bike, I manged to mate the YZF600R brake pedal to the brake rod of the GS450T drum. Nobody will ever call it beautiful, but it works. (Fabricability over form!)

There’s only about 4 mm clearance between the brake rod and the shock, but that should be enough. The spherical joint and turnbuckle are from the Ducati 620 Monster engine I bought for the Aermacchi-Ducati Special.

Mating a hydraulic brake pedal to a rod-operated drum took some ingenuity. I made up a hardboard template, then cut the bracket from a pre-bent piece of 7/32″ steel plate. I stomped down on the pedal pretty hard, and the first thing to flex was the pedal itself, so I think the rest of it is adequately strong.

To the right of the photo, at the front of the pedal, is a view of the opposite end of the gearshift cross-shaft, and the pedal stub it will connect to. More parts for this are on the way, but won’t arrive for another week or so.