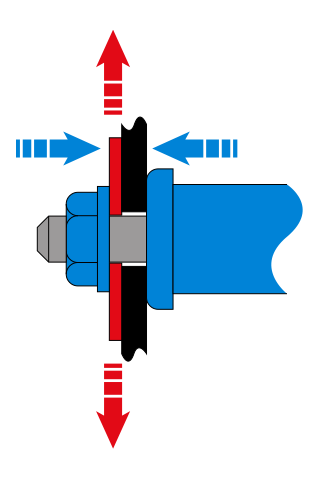

My plan to use an external plate to neck down the diameter of the frame’s existing swingarm pivot hole in got me thinking more thoroughly about what I needed. Some careful observation revealed that this escutcheon plate won’t have to deal with as much stress as I thought.

Since the OD of the swingarm bearing sleeve is greater than the existing 14mm hole, tightening the pivot shaft nut will effectively deal with the swingarm stresses in the transverse plane (the blue arrows). The only thing my new plate (in red) will have to do is locate the left side of the swingarm pivot in the vertical and longitudinal planes (the red arrows), with two mitigating factors: 1) friction from the clamping force of the nut will help absorb the stresses in the other planes, and 2) the failure mode is only 2.5″ mm of play, not sudden, catastrophic chassis failure.

Because of this, I am planning to make the escutcheon plate out of 1/8″ steel plate (the same stock I used earlier for the spacers around the rear axle slots on the swingarm) and rather than weld it on, I will attach it with two 6mm stainless steel socket-head allen screws.

I originally planned to simply drill through the frame and put nuts on the other side, but I bought a tap and I will try tapping the holes in the frame. Why? Because it will look cleaner and (more importantly to me) I have never attempted to make threads with a tap. And this project is all about gaining experience trying things I haven’t attempted before.