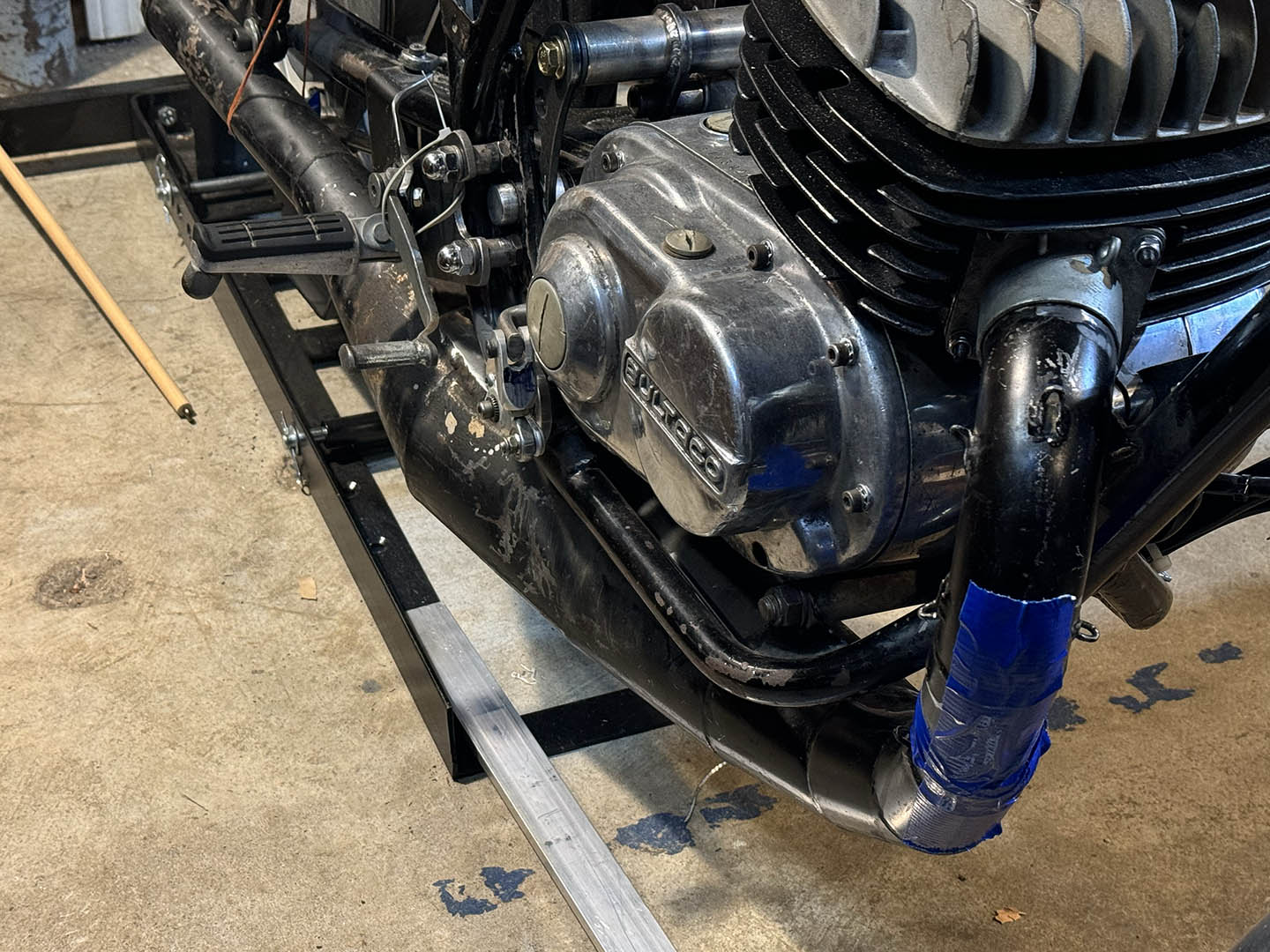

I removed the spring from my XR100 damper, and then trimmed the bottom stop rubber back so the shock can easily move through it’s normal range of travel. (As a side note, I learned that this shock is utter crap, with no discernible compression damping.)

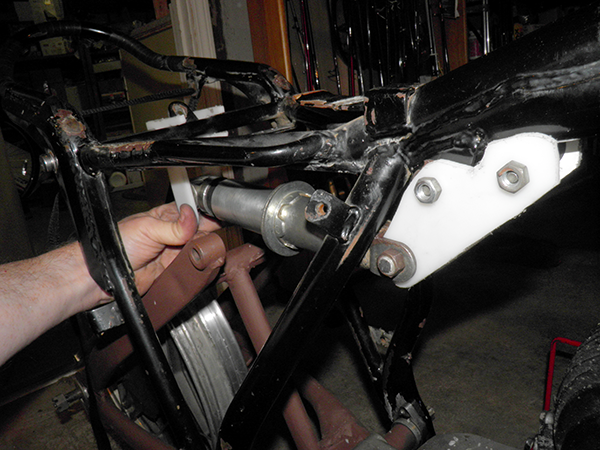

This morning before work, I started mocking up some rough patterns for my rear suspension linkages out of HDPE sheet. I still have to mock up dogbones linking the bottom of the vertical linkages to the original shock mounts on the swingarm.

PREEMPTIVE DISCLAIMER: I know the shock is bolted to some fairly wimpy frame brackets. At this point I am working strictly on determining the proper geometry — figuring out the proper means of attachment comes later. What I’m mocking up is not at all what the final mounting hardware will be.

I plan to drill several sets of shock mounting holes (high to low) on these linkages, so I can experiment with different linkage ratios. I’ll then move the rear wheel through it suspension travel in regular increments, measuring the amount of shock compression each time. By comparing damper compression to wheel movement, I can graph the ratio and see what the relationship is. I’d like to come up with a slightly progressive rate. Also, I will be able to calculate how much total wheel travel I get out of a particular amount of shock travel, which will help me choose what shock to use for real.