I welded on the extra plates needed to use the Suzuki screw-type chain adjusters. I used my 125A flux-core welder to do 5 simple plug welds per side, then gave them a quick hit with the angle grinder to smooth them off.

On the right side, the new caliper carrier and spacer went in perfectly.

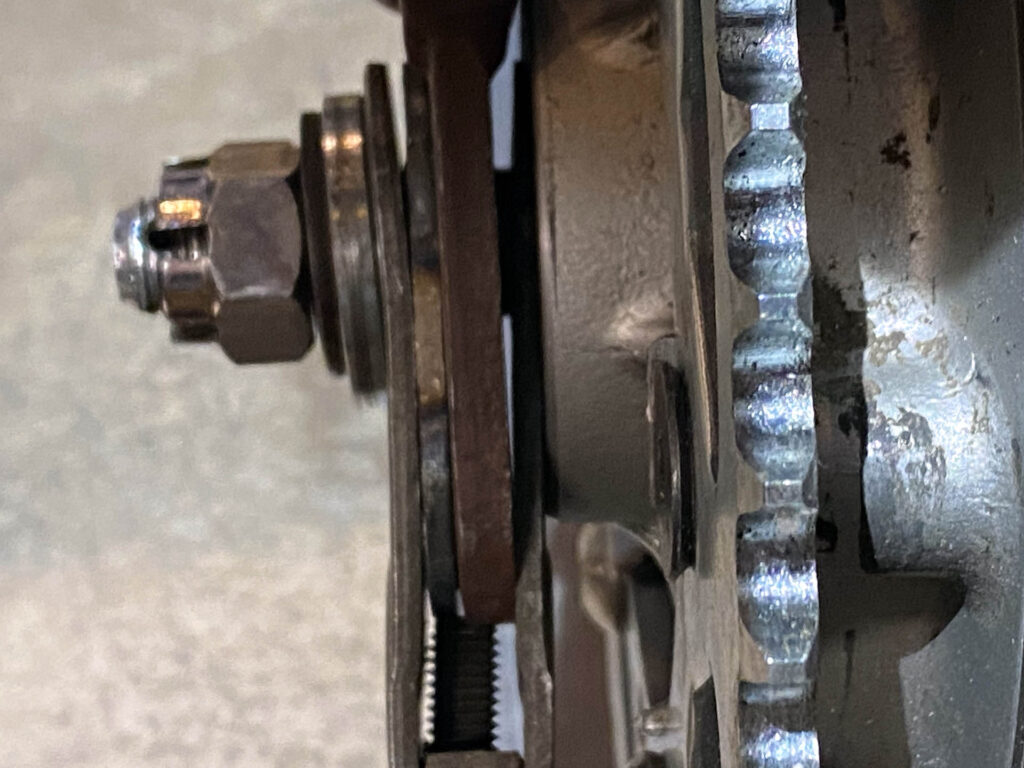

And on the drive side? Fuuuudge — I couldn’t fit the spacer in. Then, it suddenly occurred to me why I switched to the snail adjusters in the first place: there’s so little clearance between the swingarm and the sprocket carrier that I wanted to free up the space the chain adjuster plate takes up on the inboard side of the swingarm.

At first, I thought I would have to reduce the width of the spacer to compensate for the added chain adjuster plate, and perhaps make a trip back to the lathe to remove a bit more of the sprocket carrier’s bearing boss. An online friend suggested that the swingarm probably had enough flex to cope with the slight added width. The inner side of the chain adjuster only adds 3mm, so the amount of movement required would be quite minor, and certainly not enough to noticeably affect the chain alignment or wheel position.

I slipped an old, banged-up screwdriver against the sprocket carrier face and pried the swingarm outward slightly — just enough to slip the existing spacer into place. It didn’t take much force at all. Overall, I’m happy with this solution; I think I have a safe and sound configuration.